Fiber reinforced 3D printing

Fiber reinforced materials are filled with continuous fibers or fiber particles that result in parts with improved physical properties and high stiffness.

Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

Glass filled PA 12

Glass filled PA 12 contains glass particles that give parts high stiffness and improved thermal and abrasion resistance over standard Nylon.

Learn more Get instant quoteGet your parts into production today

Get an instant quote Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

Glass filled HP PA 12

HP Glass filled Nylon contains glass beads and produces parts with higher stiffness and improved thermal stability over standard PA 12.

Learn more Get instant quoteGet your parts into production today

Get an instant quote Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

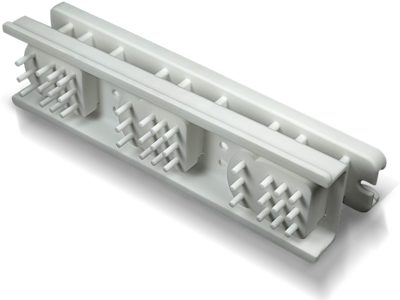

Markforged Onyx

Onyx, Markforged‘s nylon thermoplastic infused with chopped carbon fiber, is the key to achieving strong, durable prints.

Learn more Get instant quote