High strength 3D printing

High strength plastics and metals with tensile strength greater than 45 MPa.

Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

Titanium Grade 5 | 3.7164 | Ti6Al4V

Stronger than Grade 2, equally corrosion-resistant, and excellent bio-compatibility.

Learn more Get instant quoteTitanium Grade 2 | 3.7035

Stronger than Grade 1 and equally corrosion-resistant, excellent bio-compatibility.

Learn more Get instant quoteGet your parts into production today

Get an instant quote Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

PA 12

Standard PA 12 has all-around great mechanical properties and chemical resistance and is ideal for functional parts and prototypes.

Learn more Get instant quoteGlass filled PA 12

Glass filled PA 12 contains glass particles that give parts high stiffness and improved thermal and abrasion resistance over standard Nylon.

Learn more Get instant quoteGet your parts into production today

Get an instant quote Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

HP PA 12

HP PA 12 has excellent mechanical properties and chemical good resistance to chemicals. It is ideal for functional parts and prototypes.

Learn more Get instant quoteGlass filled HP PA 12

HP Glass filled Nylon contains glass beads and produces parts with higher stiffness and improved thermal stability over standard PA 12.

Learn more Get instant quoteGet your parts into production today

Get an instant quote Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

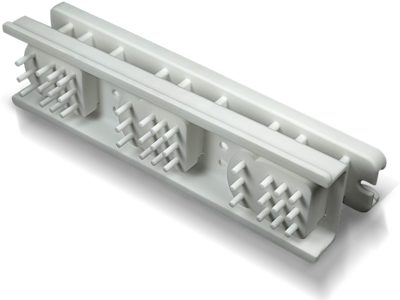

Markforged Onyx

Onyx, Markforged‘s nylon thermoplastic infused with chopped carbon fiber, is the key to achieving strong, durable prints.

Learn more Get instant quote