On Monday the 1st of October we will be switching all of our 3D printing services to our Fulfilled by Protolabs Network offering. In this post we explain why we have decided to make this change, what this means and we present some of the new features this change allows us to release.

Why we’re making this change

Protolabs Network's mission is to revolutionize manufacturing, by building a service that makes manufacturing incredibly easy and accessible. Our approach has been to provide users instant access to available production capacity for a range of manufacturing technologies through an online platform.

Early adopters of Protolabs Network originated from the DIY and 3D printing community. Makers joined the network either as a supplier (Hub) or a customer. The platform at that time was very much free-form, with the goal of serving as many, mostly one-off, custom maker projects as possible.

As the platform evolved from a peer-to-peer 3D printing network into an all-round manufacturing platform, Protolabs Network's customer base changed. Now, the majority of orders originate from professionals who source parts for larger, high value engineering projects. These users have become a key part of the business and Protolabs Network's success depends on the ability to serve these customers.

As a result, we started focusing on improving automation, standardization, and reliability of the Protolabs Network service. As part of this strategy, we launched Fulfilled by Protolabs Network at the end of 2017, as an experiment to test the impact of a more standardized order fulfillment process as discussed in this open letter.

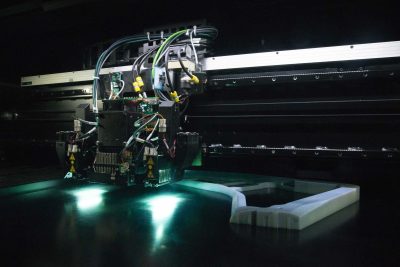

Since launching this service, we have seen explosive growth in the usage of our 3D print service, particularly by the professional user group. Customer feedback has been overwhelmingly positive and we've seen customer order value doubling since January. It has become clear that in order to reach our goal of revolutionizing the manufacturing industry, Protolabs Network needs to double down on standardization and automation of the manufacturing process. That’s why we are taking the hard decision to move away from our original peer-to-peer model and become fully B2B focused.

What does this mean specifically?

As of Monday the 1st of October Fulfilled by Protolabs Network will be the only option for ordering 3D Printed parts on www.hubs.com. Only services that are part of the Protolabs Network Manufacturing Program will be able to fulfill orders. For Protolabs Network who are not looking to run a commercial 3D printing business but still want to offer 3D printing services locally, a dedicated subsection of Protolabs Network Talk will be set up.

What's next?

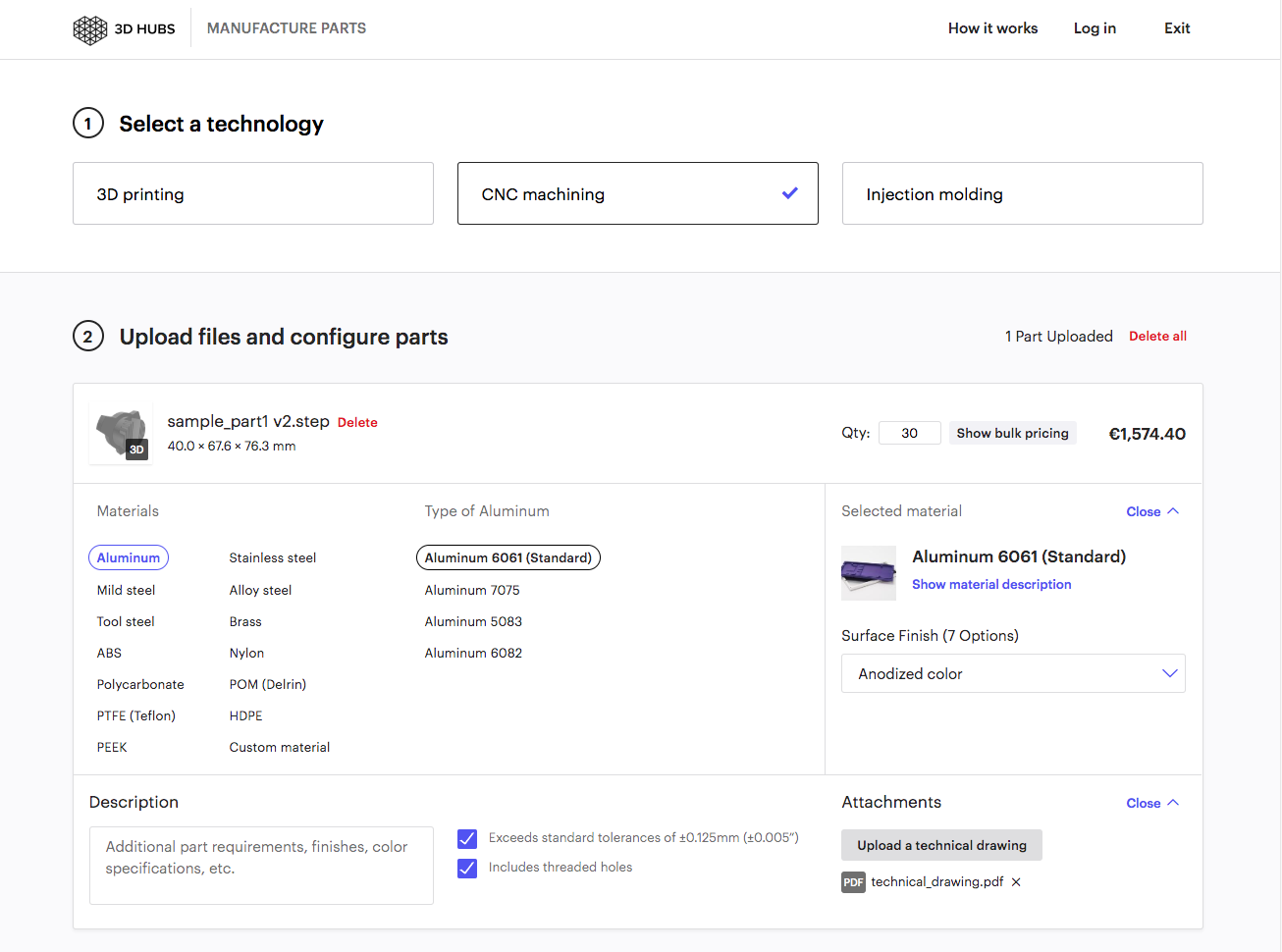

Having a standardized and simplified order flow allows us to move faster and release improved manufacturability features more often. The first platform update will be the merging of all manufacturing technologies (3D printing, CNC and injection molding) into a single checkout that includes instant pricing, smarter lead times, Design for Manufacturing (DFM) recommendations and live support.

From here on, we will be able to quickly release a range of pioneering manufacturing tools we have been working on. These tools allow Protolabs Network customers to gain more control over the production of their parts and put us at the forefront of online manufacturing.

Over the coming months some of the new features that will become available include:

Platform wide:

- Unified order management across all 3 technologies (3DP, CNC & IM)

- Customer part library for easy re-ordering and file management

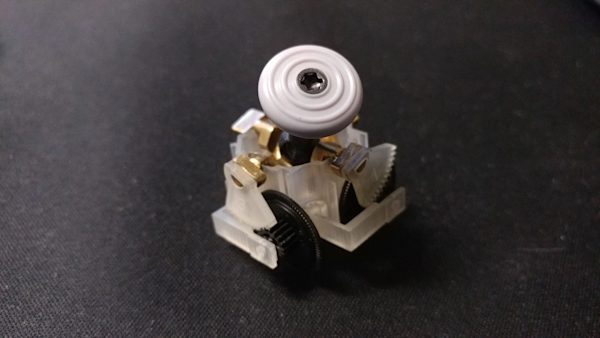

3D printing:

- Custom infill settings to achieve stronger parts, or save on material costs

- Custom print orientation for parts produced with FDM and SLS technology

- Cosmetic side dictation specifically for parts produced with SLA technology

CNC machining:

- Instant Design for Manufacturing feedback and design suggestions

- Vibration analysis to more accurately simulate manufacturability with CNC

Injection molding:

- Heat dissipation analysis, to predict part performance

- Mold separability feedback to improve part designs for Injection molding

We understand that these changes are significant, however we strongly believe that these developments will enable us to better serve our growing professional customer base going forward.

We’ve truly enjoyed building the largest peer-to-peer 3D Printing community and, with our industry evolving so quickly, the business now needs to adapt for the next stage of its journey.

If you have any questions about these updates please feel free to contact us: networksupport@protolabs.com.

Explore more on the Protolabs Network platform here.