For all our CNC machined parts we produce, we have certain standards we ensure for our deburring and primary surface finishes which include smooth machining, bead blasting, brushing, polishing, and brushed and electropolished. These standards are listed below so you know what to expect when you order CNC machined parts from Protolabs Network.

For an overview of CNC machining finishes and their pros and cons, check out this article →

Skip to:

Deburring

Deburring comes as a standard for all parts machined through Protolabs Network regardless of the surface finish. Standard option:

-

Standard is deburring and breaking sharp edges (chamfer)

-

No secondary burrs

-

Chamfer size: 0.25mm +/-0.125mm These additional options are available through our sales team as custom requests:

-

Deburring and keeping sharp edges

-

Deburring with rounded Edges

-

Deburring and breaking sharp edges to a different chamfer size

Smooth machining (1.6 Ra μm/63 Ra μin)

Standards:

- Smooth machining is like an ‘as machined’ finish but with slightly less evident machine marks

- Parts are machined with a finer step to 1.6 Ra μm/63 Ra μin

- Not hand polished

Ideal application: Smooth machining is best for precise parts where the surface roughness needs to be fine, but is not suitable for customer-facing products. For finished and/or customer-facing products, some kind of primary finish is needed, such as polishing, brushing, followed by a secondary finish, such as anodizing, plating, polishing, etc.

Bead blasting

Standards:

-

Parts will have a grainy texture

-

Finished with glass bead blasting

-

Standard grit is #120. Other available grits are #80, #100 and #150, but you’ll need to request these manually.

-

Tolerances apply to the part after bead blasting

Tolerance limitations:

- Bead blasting will not have an effect on tolerances except for holes and tolerances of +/-0.02mm or tighter

- For holes, we recommend you add masking requirements in your technical drawings

- Tolerances of +/-0.02mm or tighter may be difficult to reach

Ideal application:

Bead blasting creates a satin, textured finish. It’s best for parts where you want to hide machine marks and fingerprint marks and avoid reflective surfaces. The textured surface can also help to increase grip.

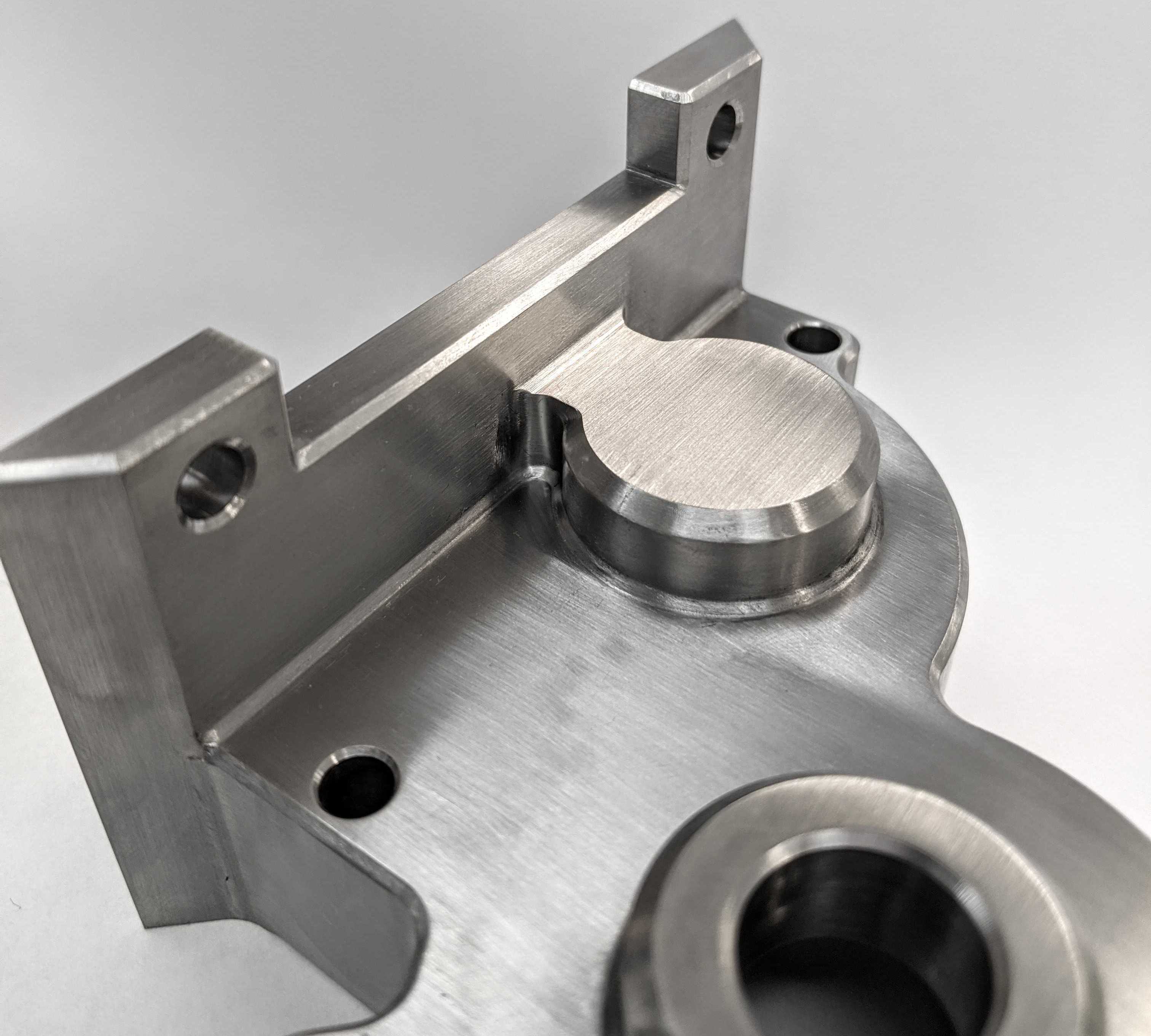

Brushing (1.2 Ra μm/47 Ra μin)

Standards:

- Brushing grit: #400-600

- Standard roughness: 1.2 Ra μm/47 Ra μin

- Machine marks are removed

- Parts are manually brushed with directional marks Ideal application:

Brushing is mostly used for aesthetic purposes and can be used to cover up imperfections from machining for customer-facing parts.

Brushed and electropolished (0.8 Ra μm/32 Ra μin)

Standards:

- Standard roughness is 0.8 Ra μm/32 Ra μin

- Parts are brushed and then run through an electropolishing process, which further reduces the roughness of the parts and make the surface more smooth and shiny Ideal application:

Brushed and electropolished creates a clean surface, best for parts that need to be smooth at a microscopic level.