3D printing with PLA vs. PETG: What's the difference?

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

This comprehensive guide compares the 25 most common materials used in CNC machining and helps you choose the right one for your application.

CNC machining can produce parts from almost any metal or plastic. This being the case, there’s a huge range of materials available for parts produced via CNC milling and turning. Selecting the right one for your application can be quite a challenge, and understanding the advantages and best uses of each material available can be crucial.

In this article, we compare the most common CNC materials, in terms of mechanical and thermal properties, cost and typical (and optimal) applications.

Did you know we offer local sourcing for CNC machining?

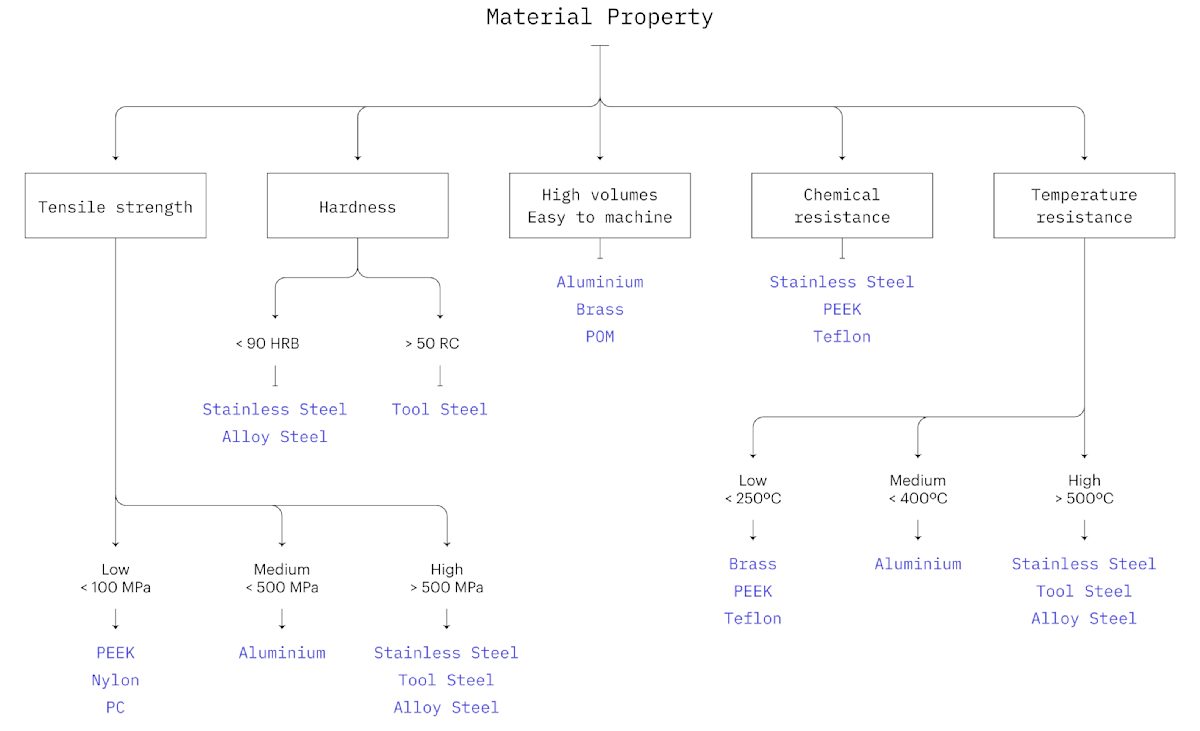

When you’re designing a part to be CNC machined, choosing the right materials is essential. Here are the basic steps we recommend following to select the right materials for your custom parts.

Define the material requirements: These can include mechanical, thermal or other material requirements, as well as cost and surface finish. Consider how you’ll be using your parts and what sort of environment they’ll be in.

Identify candidate materials: Pin down a few candidate materials that fulfill all (or most) of your design requirements.

Select the most suitable material: A compromise is usually required here between two or more of the design requirements (for example, mechanical performance and cost).

In this article, we will focus on step two. Using the information presented below, you can identify the materials that are most suitable for your application, while keeping your project on budget.

In the tables below, we summarize the relevant characteristics of the most common CNC materials, gathered by examining the datasheets provided by the material manufacturers. We split metals and plastics into two distinct categories.

Metals are mainly used in applications that require high strength, hardness and thermal resistance. Plastics are lightweight materials with a wide range of physical properties, often used for their chemical resistance and electrical insulation capabilities.

In our comparison of CNC materials, we focus on mechanical strength (expressed as tensile yield strength), machinability (the ease of machining affects CNC pricing), cost, hardness (mainly for metals) and temperature resistance (mainly for plastics).

Here is an infographic that you can use as a quick reference to quickly identify CNC materials that fit specific engineering needs:

| Material | Grade | Strength* | Hardness+ | Machinability | Cost | Typical applications |

|---|---|---|---|---|---|---|

| Aluminum | 6061 | Medium | Medium | ★★★★★ | $ | General purpose Aircraft components Automotive parts Bicycle frames Food containers |

| 6082 | Medium | Medium | ★★★★★ | $ | General purpose Automotive parts Food containers | |

| 7075 | High | Medium | ★★★★ | $$$ | Aircraft & aerospace components Automotive parts Marine applications Sports equipment | |

| 5083 | Medium | Low | ★★★★★ | $$ | Marine applications Construction Pressure vessels | |

| Stainless steel | 304 | High | Medium | ★★ | $$$ | General purpose Medical devices Food industry Marine applications Chemical processing |

| 316 | High | Medium | ★★ | $$$$ | Food preparation equipment Marine applications Architecture Surgical implants Chemical containers | |

| 2205 Duplex | High | High | ★ | $$$$$ | Oil & gas Marine applications Chemical processing Heat exchangers | |

| 303 | High | High | ★★★ | $$$$ | Aircraft components Machine parts Nuts, bolts, gears, bushings | |

| 17-4 | High | Very High | ★★ | $$$$$ | Turbine blades Marine applications Chemical vessels Oil & Gas Nuclear applications | |

| Mild steel | 1018 | Medium | Medium | ★★★ | $$ | General purpose Machinery parts Jigs & fixtures |

| 1045 | Medium | High | ★★ | $$$ | General purpose Machinery parts | |

| A36 | High | Medium | ★★★ | $$ | Construction Machinery parts Jigs & fixtures | |

| Alloy steel | 4140 | Medium | High | ★★ | $$$ | General purpose Machinery parts Tooling |

| 4340 | High | High | ★★ | $$$ | Aircraft landing gear Power transmission Tooling | |

| Tool steel | D2 | High | Very High | ★ | $$$$ | Cold-working tooling Dies & stamps Cutting tools & knives |

| A2 | High | Very High | ★ | $$$$ | Cold-working tooling Dies & stamps Cutting tools & knives | |

| O1 | High | Very High | ★ | $$$$ | Cold-working tooling Dies & stamps | |

| Brass | C36000 | Medium | Medium | ★★★★★ | $$ | Mechanical parts Valves & nozzles Architecture |

| Material | Strength* | Operating temperature+ | Machinability | Cost | Typical applications |

|---|---|---|---|---|---|

| ABS | Medium | Up to 60oC | ★★★ | $$ | Automotive Electronic enclosures Pipes & fittings Consumer products |

| Nylon | High | Up to 100oC | ★ | $$ | Automotive parts Mechanical parts Fasteners |

| Polycarbonate (PC) | High | Up to 120oC | ★★ | $$ | Architecture Automotive Electronic enclosures Food containers |

| POM (Delrin) | Medium | Up to 82oC | ★★★★ | $$ | Mechanical parts Electronic enclosures Bushings & fittings |

| PTFE (Teflon) | Low | Up to 260oC | ★★★★ | $$ | High-temperature applications Chemical processing Electronic enclosures Food processing |

| HDPE | Low | Up to 80oC | ★ | $$ | Chemical containers Pipes & fittings Consumer products |

| PEEK | High | Up to 260oC | ★★ | $$$$ | Medical applications Chemical processing Food processing High-pressure valves |

Aluminum alloys have an excellent strength-to-weight ratio, high thermal and electrical conductivity and natural protection against corrosion. They are easy to machine and cost-efficient in bulk, often making them the most economical option for producing prototypes and other types of parts.

While aluminum alloys typically have lower strength and hardness than steels, but they can be anodized, creating a hard, protective layer on their surface.

Let’s break down the different types of aluminum alloys.

Aluminum 6061 is the most common, general-use aluminum alloy, with a good strength-to-weight ratio and excellent machinability.

Aluminum 6082 has a similar composition and material properties to 6061. It’s more commonly used in Europe (as it complies with British Standards).

Aluminum 7075 is the alloy most commonly used in aerospace applications where weight reduction is critical. It has excellent fatigue properties and can be heat treated to high strength and hardness, making it comparable to steels.

Aluminum 5083 has higher strength than most other aluminum alloys and exceptional resistance to seawater. This makes it optimal for construction and marine applications. It’s also an excellent choice for welding.

Typical density of aluminum alloys: 2.65-2.80 g/cm3

Can be anodized

Non-magnetic

Stainless steel alloys have high strength, high ductility, excellent wear and corrosion resistance and can be easily welded, machined and polished. Depending on their composition, they can be either (essentially) non-magnetic or magnetic.

Let’s break down the types of stainless steel we offer on the platform.

Stainless steel 304 is the most common stainless steel alloy. It has excellent mechanical properties and good machinability. It’s resistant to most environmental conditions and corrosive media.

Stainless steel 316 is another common stainless steel alloy with similar mechanical properties to 304. It has a higher corrosion and chemical resistance though, especially to saline solutions (for example seawater), so it’s often better for dealing with harsher environments.

Stainless steel 2205 Duplex has the highest strength (twice that of common stainless steel alloys) and excellent resistance to corrosion. It’s used in extreme environments, with many applications in Oil & Gas.

Stainless steel 303 has excellent toughness, but lower corrosion resistance compared to 304. Due to its excellent machinability, it’s often used in high-volume applications, such as producing nuts and bolts for aerospace.

Stainless steel 17-4 (SAE grade 630) has mechanical properties comparable to 304. It can be precipitation hardened to a very high degree (comparable to tool steels) and has excellent chemical resistance, making it suitable for very high-performance applications, such as manufacturing blades for wind turbines.

Material characteristics:

Typical density: 7.7-8.0 g/cm3

Non-magnetic stainless steel alloys: 304, 316, 303

Magnetic stainless steel alloys: 2205 Duplex, 17-4

Mild steels are also known as low-carbon steels and have good mechanical properties, great machinability and good weldability. Because they are relatively low cost, manufacturers use them for many general purpose applications, like jigs and fixtures. Mild steels are susceptible to corrosion and chemical damage.

Let’s break down the types of mild steels available on the platform.

Mild steel 1018 is a general-use alloy with good machinability and weldability and excellent toughness, strength and hardness. It’s the most commonly used mild steel alloy.

Mild steel 1045 is a medium carbon steel with good weldability, good machinability and high strength and impact resistance.

Mild steel A36 is a common structural steel with good weldability. It’s suitable for a variety of industrial and construction applications.

Typical density: 7.8-7.9 g/cm3

Magnetic

Alloy steels contain other alloying elements in addition to carbon, resulting in improved hardness, toughness, fatigue and wear resistance. Similar to mild steels, alloy steels are susceptible to corrosion and attacks from chemicals

Alloy steel 4140 has good overall mechanical properties, with good strength and toughness. This alloy is suitable for many industrial applications but is not recommended for welding.

Alloy steel 4340 can be heat treated to high levels of strength and hardness, while maintaining its good toughness, wear resistance and fatigue strength. This alloy is weldable.

Typical density: 7.8-7.9 g/cm3

Magnetic

Tool steels are metal alloys with exceptionally high hardness, stiffness, abrasion and thermal resistance, so long as they undergo heat treatment. They are used to create manufacturing tools (hence the name) such as dies, stamps and molds.

Let’s break down the tool steels we offer at Protolabs Network.

Tool steel D2 is a wear-resistant alloy that retains its hardness to a temperature of 425°C. It is commonly used to manufacture cutting tools and dies.

Tool steel A2 is an air-hardened general-purpose tool steel with good toughness and excellent dimensional stability at elevated temperatures. It’s commonly used to manufacture injection molding dies.

Tool steel O1 is an oil-hardened alloy with a high hardness of 65 HRC. It’s commonly used for knives and cutting tools.

Typical density: 7.8 g/cm3

Typical hardness: 45-65 HRC

Brass is a metal alloy with good machinability and excellent electrical conductivity, making it ideal for applications that require low friction. You’ll often find cosmetic brass parts used for architectural purposes (gold detailing(.

Here’s the brass we offer at Protolabs Network.

Brass C36000 is a material with high tensile strength and natural corrosion resistance. It’s one of the most easily machinable materials, so it’s often used for high-volume applications.

Typical density: 8.4-8.7 g/cm3

Non-magnetic

ABS is one of the most common thermoplastic materials offering good mechanical properties, excellent impact strength, high heat resistance and good machinability.

ABS has low density, making it ideal for lightweight applications. CNC machined ABS parts are often used as prototypes prior to mass-production with injection molding.

Material characteristics:

Typical density: 1.00-1.05 g/cm3

Nylon (aka polyamide (PA)) is a thermoplastic that is often used for engineering applications, due to its excellent mechanical properties, good impact strength and high chemical and abrasion resistance. It’s susceptible to water and moisture absorption.

Nylon 6 and nylon 66 are the grades that are most commonly used in CNC machining.

Typical density: 1.14 g/cm3

Polycarbonate is a thermoplastic with high toughness, good machinability and excellent impact strength (better than ABS). It’s usually transparent, but can be dyed to a variety of colors. These factors make it ideal for a wide range of applications, including fluidic devices or automotive glazing.

Material characteristics:

Typical density: 1.20-1.22 g/cm3

POM is commonly known by the commercial name Delrin, and it is an engineering thermoplastic with the highest machinability among plastics.

POM (Delrin) is often the best choice when CNC machining plastic parts that require high precision, high stiffness, low friction, excellent dimensional stability at elevated temperatures and very low water absorption.

Material characteristics:

Typical density: 1.40-1.42 g/cm3

PTFE, commonly known as Teflon, is an engineering thermoplastic with excellent chemical and thermal resistance and the lowest coefficient of friction of any known solid. It’s one of the few plastics that can withstand operational temperatures above 200 degrees Celsius and is an outstanding electrical insulator. It also has pure mechanical properties and is often used as a lining or insert in an assembly.

Typical density: 2.2 g/cm3

High-density polyethylene (HDPE) is a thermoplastic with a high strength-to-weight ratio, high impact strength and good weather resistance. HDPE is lightweight and is suitable for outdoor use and piping. Like ABS, it is often used to create prototypes before Injection Molding.

Material characteristics:

Typical density: 0.93-0.97 g/cm3

PEEK is a high-performance engineering thermoplastic with excellent mechanical properties, thermal stability over a very wide range of temperatures and excellent resistance to most chemicals.

PEEK is often used to replace metal parts due to its high strength-to-weight ratio. Medical grades are also available, making PEEK suitable also for biomedical applications.

Typical density: 1.32 g/cm3

Our manufacturing experts can help you select the right material for your application

This depends a lot on the application in question, but overall Aluminum 6061 is the most common and lowest cost metal for CNC machining.

POM (Delrin) is the most economical plastic for CNC machining. This is thanks in part to the excellent machinability of thermoplastics.

Metals are ideal for manufacturing applications that require high strength, hardness and/or reliable resistances to extreme temperatures.

While more common in 3D printing, plastics are ideal for CNC machining when you’re looking to produce lightweight parts with special material requirements. Plastics are also viable for producing prototypes (especially before you start making larger quantities with injection molding).

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

Have you designed your parts with sharp corners? They may look good on paper, but they're a nightmare to manufacture with CNC machining. In this article, learn how and why to avoid sharp corners in your designs. It'll reduce lead times, cost and potential headaches for machinists.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

What’s the best material for machining your parts? Check out this side-by-side comparison of the strength, price and application for CNC plastics and metals (in a handy, printable poster).

Read article

What is anodizing? Anodizing is key to finishing parts made from aluminum and other metals. Learn how anodizing works and why it is an important part of CNC machining and manufacturing.

Read article

What are the different types of threads for manufacturing? In this article, learn how to correctly design threads to reduce lead times and cost for your next CNC machining production run.

Read article

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

Have you designed your parts with sharp corners? They may look good on paper, but they're a nightmare to manufacture with CNC machining. In this article, learn how and why to avoid sharp corners in your designs. It'll reduce lead times, cost and potential headaches for machinists.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

What’s the best material for machining your parts? Check out this side-by-side comparison of the strength, price and application for CNC plastics and metals (in a handy, printable poster).

Read article

What is anodizing? Anodizing is key to finishing parts made from aluminum and other metals. Learn how anodizing works and why it is an important part of CNC machining and manufacturing.

Read article

What are the different types of threads for manufacturing? In this article, learn how to correctly design threads to reduce lead times and cost for your next CNC machining production run.

Read articleShow more

Show less