When talking architectural, scale models, what is an appropriate wall thickness for 3D printing so that the model is strong enough? And is there any material that you’d recommend for such a print?

Thanks for taking the time to answering to my question!

5 Likes

It depends from the material you are using. for instance in CJP (Color Jet Printing) I would recommend 2mm wall thickness.

The thickness of the wall depend a lot on the nozzle diameter.

The standard nozzle in most printers is 0.4mm.

But I wouldn’t go below 1mm thickness for short lengths.

Why you want small thickness on the walls and about what thickness you are interesting about?

George

1 Like

Reify

4

Wall thickness depends on printing process. You can get away with thinner walls with FDM for instance. I like to use 1mm as a standard throughout the model giving it a more uniform look. Architectural models are frequently printed using CJP, but other technology can be used.

I would definitely recommend a PLA because of the sturdiness. When thickening the model make sure to offset it appropriately to match the scale. You can always use a large or medium honeycomb to add sturdiness to the exterior walls of the model.

Feel free to contact me if you have any further questions. As we are very familiar with Architecture, Engineering and 3D Models.

Best,

Sarah

Strength is relative so no hard and fast answer on wall thickness…its going to depend on the overall size of your Arch.Model. If its just floor plan walls with no ceiling then .5mm would suffice, but 1mm is easier to work with…the higher your model goes the thicker those supporting walls will need to be.

You could print in any material you wanted…PLA is probably sufficient and has the most color choices.

Left

7

Hi @Ryandir,

I always use a multiple of my nozzle. In my case.

Thickness depends on the size of the wall and the scale of the model. 0.4 mm, 0.8 mm, 1.2 mm …

Hello,

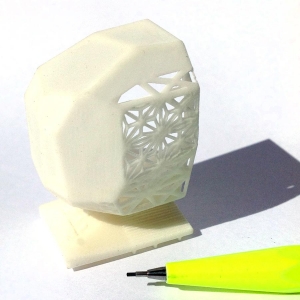

When I print architectural models on my ProJet 660 I try to design the walls so that they are larger than 1/16" thick. At this scale they may become fragile and actually end up being slightly translucent after the ColorBond infiltrant. Some examples; https://3dprinting.microsolresources.com/2015/02/06/3d-printed-gallery/ The white floor plan model in this gallery link above is at 1/8" = 1’-0" The thinest wall is almost 1/8" thick.

Roger

Hi,

I´ve printed a lot of architectural models using FFM printers: wall thickness usually depends on the scale but I would not recommend you thickness below 2mm, no matter the size of your model.

In addition, you should take in mind that details below 1,5x the diameter of your nozzle won´t be reproduced correctly, in fact I strongly recommend you that details should have at least 2x the diameter of your nozzle

Obviously is hard to say an ordinary thickness for every model, It depends on the printed model size ( i.e: is not the same to print a 20x20x20 cm model than a 5x5x5 cm one),the number of floors of your model and other particularities that are hard to explain in a general discussion.

I strongly recommend you PLA or specialized architectural filaments in order to print architectural models. The main reason is the strong dimensional stability and low warping of these filaments.

Daren

10

Ryan,

It all boils down to the scale of the model. All machines have tolerances for what the thinnest wall is. I have successfully printed models with a scale of one inch equals 30 feet. I have also printed a few models at 1/4" = 1’-0" and 1/8" = 1’ -0"

The larger the model the higher the cost. If you would like me to review your file for its printability I can take a look and advise you what your options are.

Wall thickness will probably depend on your model scale but in any case it`s always a multiple of your nozzle diameter. I have printed architectural models and others at 0.8mm wall thickness (even 0.4 on vase mode). Chosen material and desired strength depends on the shape of your model, size, how it will be handled, if it will be assembled or glued. Intricate shapes, scaled furniture or small details are best with SLA but for most parts PLA should be fine.

Wall thickness will probably depend on your model scale but in any case it`s always a multiple of your nozzle diameter. I have printed architectural models and others at 0.8mm wall thickness (even 0.4 on vase mode). Chosen material and desired strength depends on the shape of your model, size, how it will be handled, if it will be assembled or glued. Intricate shapes, scaled furniture or small details are best with SLA but for most parts PLA should be fine.

all are right, scale will determine the thickness. I print in Z scale, and have to compromise on the thickness. For instance a normal 220mm wall could hardly show any mouldings at 1:220 scale and have to be made slightly thicker than scale to show. How do you scale an angle iron frame of 50mm? 0.2mm is not practical to print. I do the wall thickness 2.4mm to have it sturdy. My 2 cents!

Rapid

14

With SLS, above 2mm, any wall is really solid. The Polyamide 12 is translucent under 2mm, so even the glass of windows can be 3Dprinted thinner to show by translucency when backlit. The second picture attached has solid walls as thin as 0.4mm (400microns) but they are supported all around and are not longer than 10-15mm.

1 Like

Daren

16

Wall thickness is limited by the dimensions shown in the printer information. This machine has a .3 mm tolerance for a supported wall. That is really detailed.

Mirth

17

For a strong model, 1mm thick walls and PLA should do perfectly. I use 1.5mm for mechanical parts, 1mm for strong parts and so on. Under 1mm I start measuring by perimeters.

What is the overall size of your model?

What scale are you printing at?

What is the size of your Extrusion head? .4mm or other?

You need to know your printer, filament and its capabilities really well, before you go and attempt a large detailed model.

Knowing your printer will help you reduce the chances of a mistake in the print.

PLA is strong and ridged but it breaks easy when pressure is applied to the perpendicular of the wall or surface.

ABS is slightly more (flexible) and my not break as easy when the same pressure is applied to the wall. I sure you don’t want your model to bend or warp over time.

PLA is a good choice. The thicker the wall is the better it will hold up.

All thickness min 1 mm. PLA is ok. All scales