Hey users,

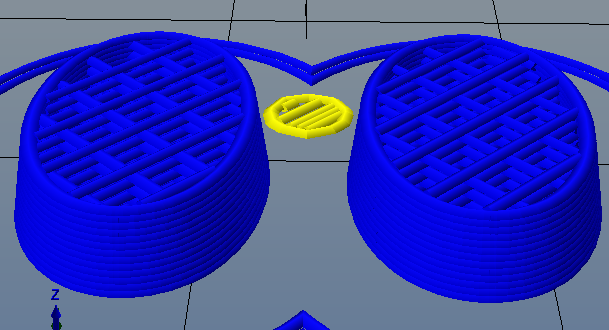

My name is Josh and I’m new to 3DHubs. I’m trying the test print but having issues constraining to the printing instructions. The printing instructions specify to print without support, but the geometry of the supplied model inhibits this request. I’ve attached two images highlighting the problem geometry, that without support creates ‘free-hanging’ slices that will cause printing errors. How would I approach printing this?

.

3 Likes

Because the “bridge” of the marvin is so small, the majority of the plastic layer is supported by the previous layer below it. There may be some drooping, but I would give it a try without supports to see what happens

I did, it creates a small goober of plastic that messes up the adjacent slice. Its nothing detrimental, I can sand it off. But is that whats expected?

All about the cooling. I have a pretty aggressive fan that cools the PLA very quickly after its extruded. That helps immensely on bridging - especially for gaps as small as Marvin’s.

The thinner you slice the layers, the less of an issue this bit is.

if you use Simplify3D software, you can manually apply support for Marvin to be on the safe side

3 Likes

- I’ve been wondering about that slicer, I’ve heard a lot of good things about it, just not sure if the investment is worth it. Have you used ‘Repetier-Host’ & the Cura Engine? If so how does it compare to the pathing of ‘Simplify3D’?

- I check there site and the product brochure states that is has ‘Unrivaled slicing performance’, does that mean it just slices faster or is the pathing enhanced as well? Sorry to grill ya with questions, I just would really like a user’s opinion of the software and not some sales pitch from the developer.

The Fix I used:

- I just deleted the free hanging section out of the GCode and set the extruder with a G92 so that the extrusion stepper wouldn’t try to push the removed section of material in the jump.

- Thanks for the help guys, they were all really good tips.

I cannot say because i quited using Repetier one and a half year ago. They ( software) all searching for new feature and Simplify was the user-friendliest at that time.

I use simplify3d and just had to add a cooling fan and slow the print speed.

As i said before, small part always duplicate to let the other one cool down a bit

i know your comment is 4 months old now, hopefully this will still be relevant to you:

I recently upgraded from Repetier-Host, Cura, and Slic3r, to S3D. The difference is immediately noticeable. slicing times are wicked fast, surface finish of printed parts is much nicer, the support material is an absolute dream, it works. it ACTUALLY WORKS!

In other news, i swear my printer is actually quieter now, at the same speeds, i experience zero oozing, and ive never had a print failure at all. I bought it from PrintedSolid, who pledged to give me any support i needed, but i’ve not needed any.

HooeyB

13

change the default extrusion from o(auto) to your nozzle diameter and you;ll see that part of the print is acutally connected to the inner side of the legs. I know that your post is a year old but i also know that with 3D printing you never stop learning.

1 Like