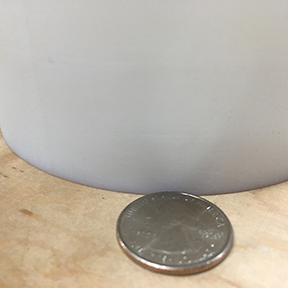

Hi, I’m printing with Objet 30 Pro. I printed a part that has lines running down the side for some reason. The lines only seem to exist where there is graphics visible on outside of print. The rest of the print is totally smooth. It was printed in the position shown. The same print was aborted half way through a few days before this print and the same lines appear in the same places, so I think it must be how I’m preparing the .STL file. The part was made in Solidworks and saved as .STL

The lines do not appear in the solidworks file or when I reopen the .STL in Solidworks

Any thoughts on what is causing the issue would be helpful, Thanks!

it’s happen when there is a cavity on the side. it’s the support effect…

I’ve seen this before on an Eden and a 30. Two questions; have you recently been running Duruswhite? How often do you clean your heads? This can be one of two things, the machine needs to be calibrated or you have a blockage in the nozzles of the model head on one side. Was the ’ bumpy ’ side printed facing up or to one side? You will need to perform a pattern test to check your nozzle output. You could then try to clean out the offending nozzles with isoproponol. There is no easy way to say this but I think you may need a new head. Not cheap! Stl’s output from Solidworks are not the problem though, you can rule that out.

Hi Steve

As mentioned in an earlier post, I also think it’s to do with the support material. If you could show a picture of the part further up, to see if there’s any detail that had support on. If so this would also have an overhang of support which runs down the length of the part.

Regards

Adam

Hi, I agree, the Objet 30 Pro adds support material below embossed details (or through-holes) on vertical walls for stabilization purposes.

After removal of the support what’s left usually is those carved features like the ones in your image.

Unfortunately in your picture it doesn’t show if those “lines” are going all the way up the model or if the lines stop at the top of the embossed symbol -maybe you can provide a picture with more image detail?

Cheers, Sebastian

The lines go all the way to the top… around 6 inches.

The lines are made of the resin material they are not the support material.

Was the part printed on it’s side and the lines are forming on the top but not the bottom?

The lines are resin, not support material

The lines are the hard resin and not the support material. They run from top to bottom 6 inches and run half way around the 5" wide cylinder, but only where there is graphics printed into side of cylinder. The cavities also show the lines inside. The rest of the cylinder is completely smooth.

I printed another piece about this size last week and there were no lines at all.

It was printed in the position shown, it printed the cylinder in a vertical path

I do not know whether clogged heads are the issue, I don’t run the machine. I just don’t see why the other half of the cylinder is flawless and smooth

That is strange then. I suppose I could be wrong and it may be in the file generation from the software… but if it printed fine last time and it’s the same stl. it’s got to be the model head. I reckon the nozzles are blocked on one side. I know it’s an expense on material but the best way to eliminate that is by turning the part around on the print bed and printing the cavity section on the opposite side to see if it turns out smooth. Then you’d know. Have you printed something else and got this effect? If not, it’s the file.

1 Like

I printed a similar large tapered cylindrical piece a week before and it printed perfectly fine. Then this piece was printed and there was a power outage and I was left with just 2" of the piece. It was printed again and all the lines appeared in exactly the same place again. There are so many preferences in the setup of the STL file that I’m thinking maybe a combination of settings created those lines. If that was the case, it seems like I would see the lines after I opened the STL file to examine it?

True. You would expect to see them in the software. I know there is a slight deviation on anything circular printed on the Objets but not to that extent. If this is the only file that is printing like this then it’s not the machine. Would love to hear how you get on? I reply to issues but never hear if they were resolved! I always hope that’s a sign the problem’s fixed! Good luck!

1 Like

Dear all, it’s a common effect where there is a side hole: after you wash away the support, the resin lines remain.

there shouldn’t be but it’s a common problem…and well known, unfortunately!

Ok, do you have any references or links to other examples with this problem? I made a similar print that had a compound curve and a relieved graphic and it printed fine. The one that failed had a tapered curve… not sure if that means anything… My suspicion is that it is a combination of preferences when creating the .STL output file that causes this problem.

This is expensive to reprint so I would like to figure out what the problem is… Thanks!

PROBLEM I HAVE HAD…STILL NO SOLUTION