Hello all,

I am using a QiDi Tech 3DP-QDA16-01 printer for work.

Recently I have experienced a loose extruder body and a filament leak above the nozzle.

The printer lays down the first layer of the raft properly then there is hot filament coming from the back and up above of the extruder body.

I am hesitant to tighten it until I can do this properly.

Researching online, I have yet to find a video that can describe how to do this.

Any assistance will be helpful.

TIA/Artie

Picture attached.

1 Like

From the picture it’s really hard to tell where is the leak point but it usually happens when the nozzle is clogged and the filament forces itself out any way it can. It shouldn’t happen with a good nozzle even with a loose assembly. I think you need to get a new nozzle.

1 Like

If it is the square block that is loose then you may be able to turn it slightly and see if it tightens back up. Just be carefull of the wires going to it as they are fragile.

Something you may want to consider is getting a second extruder assembly from QIDI. They are not expensive and that way you can always have one ready to go.

This is the lower part.

https://www.ebay.com/itm/QIDI-TECHNOLOGY-a-set-of-Aluminum-block-with-cable-for-QIDI-TECH-I-3d-printer/331747178368?epid=716371310&hash=item4d3dac3780:g:euYAAOSwwPhWi11a

This is the whole thing. This goes for 285 on Flashforges site and is the same thing.

https://www.ebay.com/itm/QIDI-TECHNOLOGY-dual-extruder-3d-printer-high-speed-and-high-quality/331584942883?epid=716241708&hash=item4d3400b323:g:gigAAOSwHnFVgjDU

If not then you will need to dismantle the hot ends and extruder assembly to get everything reset properly.

Maybe check out the facebook group “QIDI 3D” there is a lot of good help there.

SLArtie

4

@shahramrobotics-

Not a real good picture of the leak, I was trying to point out which extruder blk was loose.

Leak is actually hidden above the aluminum body up where it attaches to the rail assembly.

I did manage to slightly tighten the block but was concerned that the two head touching each

other would create undo heat/other problems. Will give it a test run and monitor closely.

The filament flows well when temp is reached and the 1st layer raft lays down well.

SLArtie

5

@wirlybird

Thanks for those linkies for replacement parts.

Anticipating using the 2nd option to minimize down time and sort out the “why” in due course.

Will revert with results.

That’s what I did once. Don’t remember the issue but I saw the price for the whole setup and went for it. Pretty much a bolt on and was back up and running. Now have a spare all setup and ready. Eventually I’ll get around to making a quick disconnect for all the wires to simplify a change over even more.

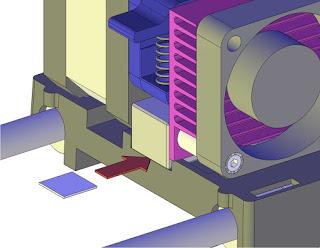

As a side note, one thing that seems quite common is the right extruder always seems to be just a bit lower than the left. Here is an easy remedy if either side is slightly low. Use a couple little pieces of paper or foil as shims - See the pic.