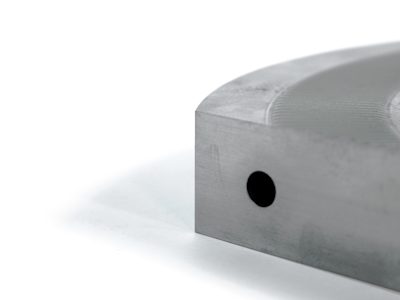

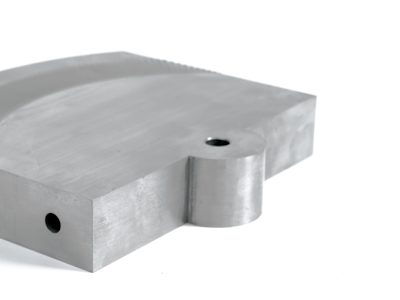

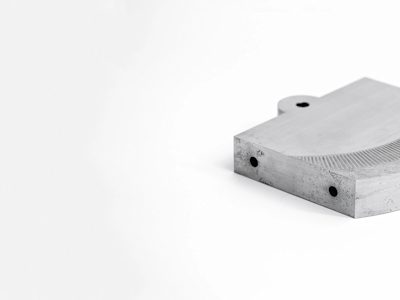

CNC machining materials

CNC machining in Tool steel

High hardness and stiffness, abrasion resistant. Tool steels are metal alloys with exceptionally high hardness, stiffness and abrasion resistance. Suitable for manufacturing industrial tools.

Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

Tool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Tool steel D2 (CNC) is a wear-resistant alloy that retains its hardness to a temperature of 425 °C. Used for cutting tools and dies.

Learn more Get instant quoteTool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state

Tool steel A2 (CNC) is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Learn more Get instant quoteTool steel O1 | 1.2510 | 100MnCrW4 - Annealed state

Tool steel O1 (CNC) is an oil-hardened alloy with a high hardness of 65 HRC. Used for industrial knives and cutting tools.

Learn more Get instant quoteTool steel A3 - Annealed state

Tool steel A3 is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Learn more Get instant quoteTool steel S7 | 1.2355 | 50CrMoV13-15 - Annealed state

Tool steel s7 has very high impact properties. Suitable for tool and die application..

Learn more Get instant quoteTool steel H13 | 1.2344 | X40CrMoV5-1 - Annealed state

Tool steel H13 has an excellent combination of high toughness and fatigure resistance. It is the most common tool steel used in tooling applications.

Learn more Get instant quote