What materials have the best repeatability?

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

What are the limitations of modern 3D print manufacturing? This article covers the major factors that will affect the quality of your 3D-printed part, including size, element thickness, how watertight it is (manifold) and curved surfaces. Read on to understand the limitations of 3D printing.

3D printers are enormously flexible in the kinds of parts they can produce. Depending on the type of printing technology, you can manufacture parts of many different sizes and geometries. However, even the most advanced 3D printing methods have their limitations.

This article explores geometric and size limitations you should understand when designing 3D models in CAD to be manufactured with additive technologies. These limitations are important to consider whether you’re producing basic mechanical components or super complex parts (and anything in between).

We also have a comprehensive step-by-step guide on exporting your 3D models into the STL file format.

One of the major limitations that every 3D printing technology faces is the size of the part it can create.

Of course, this will differ depending on the kind of printer you’re using to manufacture parts, though a good rule of thumb is to use an industrial printer for more sizable parts. We also recommend splitting parts into two or more components to be printed separately and assembled after. Both of these options will affect the final cost.

The table below showcases the typical build size of the 3D printing processes we offer at Protolabs Network (and through Protolabs in the case of metal 3D printing).

| Typical build size | |

|---|---|

| FDM | 200 x 200 x 200 mm for desktop printers; Up to 900 x 600 x 900 mm for industrial printers |

| SLA | 145 x 145 x 175 mm for desktop printers; Up to 1500 x 750 x 500 mm for industrial printers |

| SLS | 300 x 300 x 300 mm (up to 750 x 550 x 550 mm) |

| DMLS/SLM | 250 x 150 x 150 mm (up to up to 500 x 280 x 360 mm) |

| MJF | 380 x 285 x 380 mm (14.9’’ x 11.2’’ x 14.9’') |

Another major factor to keep in mind when designing a part for 3D printing is the thickness of all the walls. Every 3D printing process has a standard minimum wall thickness (or at least a highly recommended one).

In general, it’s impossible to print very thin features unless they are wider than the minimum printable feature size for a given additive process. We often see architects and game designers attempting to produce elements in a 3D model with infinitesimal thicknesses (think hair, capes and sails). This is challenging for even the most advanced printer, so be aware of this particular limitation.

The table below summarizes the recommended minimum wall thickness for the most common 3D printing technologies. Note that in some cases, like SLA, it’s possible to print smaller features, but this should be assessed on a case-by-case basis.

| 3D printing process | Recommended Minimum Wall Thickness |

|---|---|

| FDM | 0.8 mm |

| SLA/DLP | 0.5 mm |

| SLS | 0.7 mm |

| MJF | 0.5 mm |

| DMLS/SLM | 0.4 mm |

Every 3D model intended for 3D printing should be completely manifold (aka watertight), meaning that every edge should be connected to exactly 2 polygons and the model must include no holes (unless they’re integral to the design).

Models that are not manifold might get misinterpreted by the software that generates the instructions for the 3D printer (slicer). A non-manifold 3D model might cause the print itself to have inconsistent layers, holes or other errors. This will render your desired object very likely unprintable.

Let’s quickly break this down. Every model is built out of polygons, which are also called faces. These are the flat squares you see in polygonal models (non-CAD models). Every sigle polygon is the surface between 3 or 4 edges, and every one of these edges needs to have 2 polygons connected to either side of it.

Still wondering why we call models watertight, though? The reason is that if you were to fill an object up with water, a manifold model wouldn’t let a drop of it escape. This doesn’t have anything to do with whether a 3D object is water resistant or can survive being submerged for prolonged periods.

Non-manifold issues are often not visible at the modeling stage. The simplest way to check whether a model is printable is to use an analyzer software, like Netfabb or Meshmixer. These programs detect model features that will cause issues at the 3D printing stage and offer repair options (without impacting the overall geometry of the model).

Also when you upload a part to print with Protolabs Network, our automatic tools will check whether a design is printable with the most common 3D printing processes and we will show you the areas that have errors.

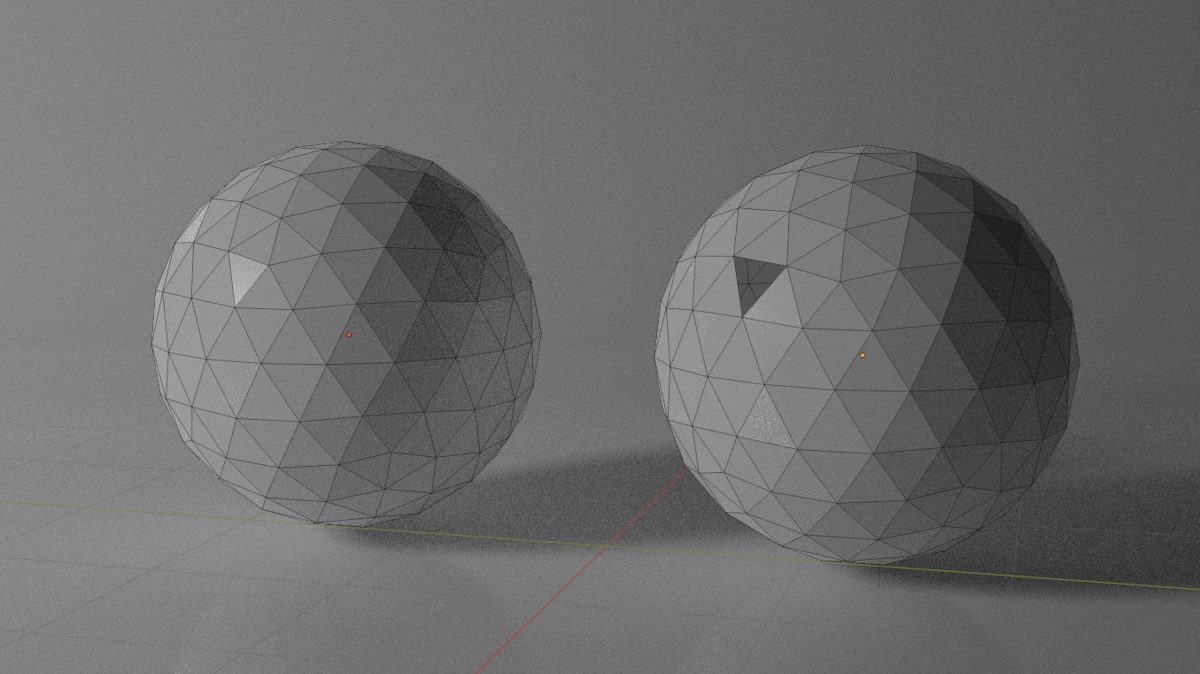

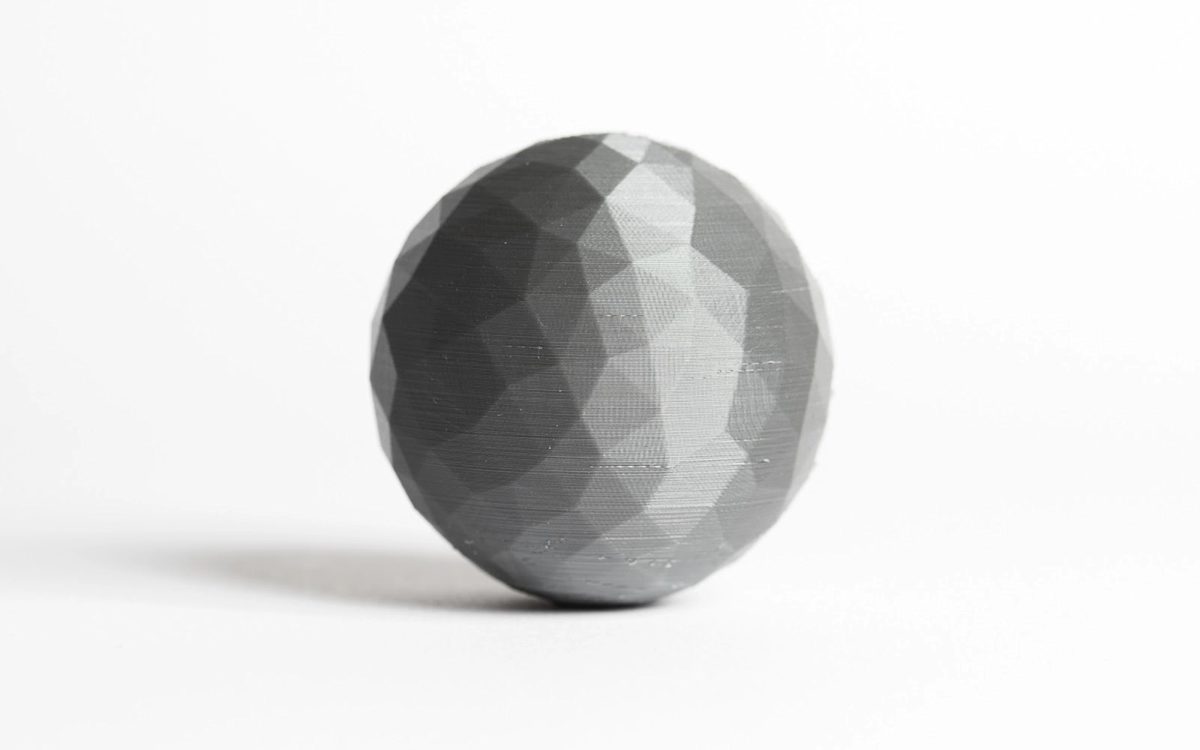

Most CAD modeling software, such as Solidworks and Fusion360, use Non-uniform Rational Basis Splines (NURBS) to display the surfaces of a 3D model. When exporting your model to the STL file format for 3D printing it’s important that an adequate number of polygons are used to represent its surfaces. This will ensure that your part will be 3D print with a smooth appearance.

If the 3D model is exported with too few polygons, the edges connecting individual polygons will often be visible in the final 3D-printed part. This effect is more prominent with large models (larger than 300 mm3), where the polygons become more visible on curved surfaces.

If you export your 3D model with too many polygons, then the file size will be too large and difficult to handle for most printers. When you create meshes of polygons, the finer the mesh (meaning more polygons), the bigger the file size, so anything below that threshold will not print (or won’t print to the right quality level).

Luckily, most modeling software export 3D models with an adequate number of polygons using the preset, resulting in smooth 3D-printed parts. If a higher polygon count is required, the export settings can be adjusted accordingly.

Ready to explore what's possible with 3D print manufacturing?

Our online 3D printing service Upload a CAD file for a free, instant quote

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Multi Jet Fusion (MJF) 3D printing can create highly accurate, complex industrial parts more efficiently - and potentially more cost-effectively - than other industrial 3D printing processes. This article covers how to design parts for MJF, common applications of the technology and key best practices.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

Learn how to avoid low quality 3D prints or unnecessarily large files by exporting your STL file in the correct resolution.

Read article

What are the different materials available for SLA 3D printing? This article compares the main printing resins, including standard, tough, durable, heat resistant, rubber-like, dental and castable, by material properties. Find the best material option for your application.

Read article

A comprehensive guide on designing parts for Binder Jetting, covering the printing process, design specifications and material options.

Read article

How does 3D printing accelerate innovation in the aerospace and aviation industry? In this article, we explain how 3D printing and additive manufacturing are commonly used in aerospace and how they improve prototyping and end-use part production for these industries.

Read article

What are the most common STL file errors and how will they affect your ability to export models for 3D printing? Learn to identify the errors you may encounter when working with STL files and how to fix them so they don't delay your next 3D printing run.

Read article

What is CAD modeling and why is it an essential tool for digital manufacturing? Explore the types of CAD software available for bringing ideas into the physical world via digital 3D modeling. Find the right software tools for your application.

Read article

This article explains how to design Material Jetting 3D printed parts including technical design specifications, materials, limitations and an introduction into the post-processing options available.

Read article

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Multi Jet Fusion (MJF) 3D printing can create highly accurate, complex industrial parts more efficiently - and potentially more cost-effectively - than other industrial 3D printing processes. This article covers how to design parts for MJF, common applications of the technology and key best practices.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

Learn how to avoid low quality 3D prints or unnecessarily large files by exporting your STL file in the correct resolution.

Read article

What are the different materials available for SLA 3D printing? This article compares the main printing resins, including standard, tough, durable, heat resistant, rubber-like, dental and castable, by material properties. Find the best material option for your application.

Read article

A comprehensive guide on designing parts for Binder Jetting, covering the printing process, design specifications and material options.

Read article

How does 3D printing accelerate innovation in the aerospace and aviation industry? In this article, we explain how 3D printing and additive manufacturing are commonly used in aerospace and how they improve prototyping and end-use part production for these industries.

Read article

What are the most common STL file errors and how will they affect your ability to export models for 3D printing? Learn to identify the errors you may encounter when working with STL files and how to fix them so they don't delay your next 3D printing run.

Read article

What is CAD modeling and why is it an essential tool for digital manufacturing? Explore the types of CAD software available for bringing ideas into the physical world via digital 3D modeling. Find the right software tools for your application.

Read article

This article explains how to design Material Jetting 3D printed parts including technical design specifications, materials, limitations and an introduction into the post-processing options available.

Read articleShow more

Show less