When to use 3D printing vs when to use injection molding

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Delrin is an engineering thermoplastic that offers low friction, high stiffness and exceptional dimensional stability. It can be used to create highly precise parts thanks to its impressive material properties, such as high strength and wide operating temperature range (-40 to 120 degrees Celsius). As well, Delrin has excellent mechanical properties and is tougher than ABS.

This article explores the material properties of Delrin and provides tips on working with this versatile and robust material. Whether you’re looking to CNC machine, injection mold or 3D print custom parts, this resource will help you understand what Delrin’s made of and when to use it.

Did you know we offer local sourcing for CNC machining?

Delrin or POM-H (homopolymer acetal) is part of the POM material family, the other POM being copolymer acetal (POM-C). It was first discovered by Hermann Staudinger, a German chemist, in 1920, later being commercially synthesized at DuPont in 1956.

Delrin is created by distilling hydrocarbons into fractions. These can be combined with other catalysts via polymerization to produce a finished plastic material. In fact, Delrin is the specific version of acetyl resin first manufactured by DuPont.

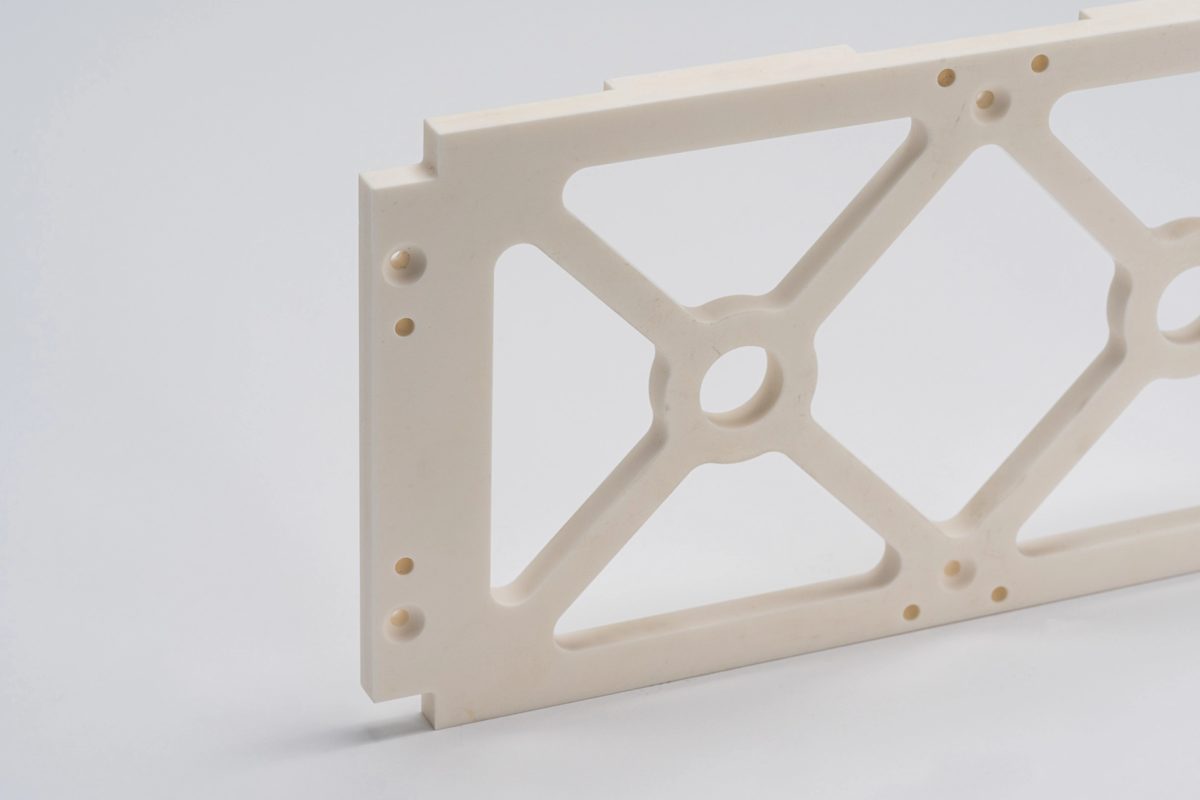

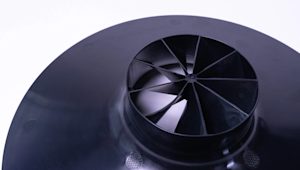

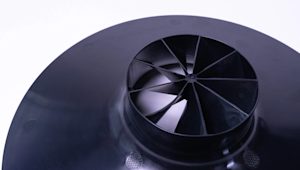

Delrin is preferred by many machinists as it’s easy to work with and can be machined using 3- and 5-axis machines, similar to metal parts. It can also be 3D printed and injection molded, making it versatile and a viable plastic for a broad range of applications.

You’ll likely find Delrin components in the automotive and consumer electronics industries, as well as any sector that needs high-performance engineering components. Typical applications for Delrin parts include high-performance parts like gear wheels, housings, screws, nuts, pump components and a whole lot more.

Electrical engineering components including connectors, electronic parts, covers and insulators can also be produced using Delrin. You can use Delrin to produce vehicle parts, including door locks and articulated shells. As well, Delrin is present across medical products and technologies, such as insulin pens and metered dose inhalers. Delrin is also a go-to option for replacing metal parts.

Delrin offers several quite impressive properties, making it a standout option among both plastics and metals. Its high strength and stiffness make Delrin ideal for applications requiring parts to carry heavy loads while being able to maintain its original dimensions and shapes when subjected to humidity and temperature changes.

Delrin also has excellent resistance to impact and creep, and to exposure to fuel and solvents as well. If your parts need to operate in the petrochemical industry without degrading, for instance, then Delrin is a sound go-to material.

Given this list of excellent material properties, Delrin is a good choice for industrial, automotive, aerospace, energy, healthcare and consumer applications. It’s optimal for products that deal with excessive moisture, like kitchen appliances, pump and valve parts and water management controls, and is even an excellent material for sports equipment, food containers and glasses.

Speaking on behalf of the machinists producing your parts, Delrin has excellent machinability. It can be cut into a wide variety of geometries using many types of tools and is ideal for injection molding and extrusion processes.

One consideration to remember when choosing a manufacturing material is component assembly. Delrin parts can be assembled in a variety of ways. You can use self-tapping screws, snap-fits and press-fits to assemble and disassemble Delrin parts, and welding, adhesives and riveting are permanent assembly operations.

If you have a large, complex assembly, you can use adhesives for prototypes or smaller production runs, but they don’t have enough strength for end-use performance. We recommend using bonded joints if performance is critical.

Remember to clean and degrease surfaces with sandpaper or with chemicals for improved assembly results.

There are two main variants of POM: POM-C (copolymers) and POM-H (homopolymer). Delrin is the commercial name for POM-H, while POM-C is known in the industry as acetal. One of the key differences between the two is their disparate melting points. POM-C starts to melt at temperatures of 160-175 degrees Celcius. A bit more robust, POM-H’s melting point is between 172-184 degrees Celcius.

Overall, POM-H has better mechanical and physical properties than POM-C, being better suited for applications where you need solid abrasion resistance and a low friction coefficient. POM-C is not as strong or as stiff as Delrin, though it is easier to process and works well in low friction applications.

As a high-performing engineering thermoplastic, Delrin has a host of unique material properties. These include:

Excellent dimensional and geometric stability

Reliable machinability

Resistance to wear and fatigue

Good heat and chemical resistances

Shiny surface and opaque white color (natural form)

In many cases, you can use Delrin in place of various metals and as a viable 3D printing material. Delrin owes these properties to its chemical composition and a high degree of crystallinity. Some of Delrin’s chemical benefits are:

Toughness at lower temperatures (as low as -40 degrees Celcius)

High mechanical strength

High rigidity

Endurance against fatigue

Impact and moisture resistance

Ease of fabrication

Insulating characteristics for electrical use

Solvent and neutral chemical resistance

However, while Delrin is more resistant to rapid failure from exposure to organic compounds than other plastics, its susceptible to strong acids, strong bases and hot water and steam.

Ultimate tensile strength: 60 - 89.6 MPa

Yield strength: 48.6 - 72.4 MPa

Young's modulus (modulus of elasticity): 2.5 - 4 GPa

Elongation at break: 15 - 75%

Hardness: 14.6 - 24.8 HV

Maximum service temperature: 76.9 - 96.9 degrees Celcius

Thermal expansion coefficient: 75.7 - 202 10^-6 / degrees Celcius

Thermal conductivity: 0.221 - 0.35 W / (m - degrees Celcius)

UV resistance: Poor

ESD Safety: Yes

Delrin can be machined using standard machine shop equipment by drilling, milling, turning, threading, sawing and tapping. We recommend taking these properties of the material into account when machining. The stiffness is lower so thin walls must be supported to avoid deflection and the thermal conductivity and melting point are lower so the heat generated needs to be minimal.

You can finish Delrin parts two ways depending on the cosmetic requirements and application of the components. As machined Delrin parts are generally good to go, though they will have machine marks and be somewhat rough along the surface. Bead blasting is the other viable option. This gives the part a uniform finish and improves its durability.

There are several surface customization options available for giving final touches to Delrin parts, including hot stamping, silk screen printing, painting, laser marking, metalizing and pad printing.

If you opt for painting Delrin parts, you can bake them at temperatures up to 160 degrees Celsius. Surfaces can also be metalized with copper, chrome and aluminum coatings for improved cosmetics and durability. Delrin parts can be laser marked and pretreated with mildly acidic solutions.

Delrin is relatively easy to work with and machine and is very stable, which makes tighter tolerances easy to achieve. However, shrinkage tends to be an issue for large parts. Large Delrin parts may shrink by +/- 0.05 mm.

Delrin is one of the most machineable plastics, which renders it more expensive than many other plastics, but very much worth the cost. And critically, Delrin doesn’t deform or lose its shape when you machine it, and it’s less likely to break thanks to its high rigidity.

While Delrin is a robust material solution for many applications, it does come with its own set of disadvantages. One of these drawbacks is that the material is tricky to bond, as it doesn’t respond well to many adhesives and solvent-based glues don’t dissolve Delrin’s surface properly. It’s also flammable after a certain amount of heat, so may deform during machining if temperatures get too high.

Delrin shares design restrictions with a ton of different materials—in fact, there aren’t many specific restrictions attributed to Delrin, but it’s important to pay attention to the more general rules to maintain tight tolerances and avoid deformation and breakage.

When designing parts for CNC machining, for instance, remember to incorporate internal radii at corners as opposed to 90-degree angles. CNC milling machines have cylindrical tools, which makes it difficult to cut 90-degree angles. Incorporating radii will save money and machining time, and remove a potential headache for machinists.

As well, you should avoid tight tolerances when possible, unless they are absolutely necessary. Not all custom components need tight tolerances. This tactic will also reduce costs and machining time.

On top of these methods, you can also avoid thin walls and deep cavities in your designs. Thin walls take longer to machine and can sometimes lead to your part being damaged during production. These kinds of design considerations may require more specialized machines, which will come at a higher cost. Also, try keeping the size of your threads less than 3 times the diameter of the holes. Deeper threading increases machining time and, as you guessed, cost.

Ready to start producing custom Delrin parts?

See if Delrin's right for your design Upload a CAD file for a free, instant quote

Delrin is slightly harder than types of acetyl plastic.

Delrin is a very durable and strong material that can be used for a variety of applications. It’s a good choice for parts that will get wet and for thinner, lightweight components. Delrin is very resistant to fatigue and impact and won’t likely permanently deform.

In terms of strength, durability and wear resistance, Nylon is one of the most similar materials to Delrin. Both materials are resistant to UV light and many chemicals and have a low friction coefficient.

However, Nylon is a better option if you’re looking to 3D print parts, and there are many types and grades of Nylon to choose from. It’s more suited to higher temperature applications than Delrin, though Delrin is far superior when moisture or damp environments are involved.

Delrin can become brittle when exposed to low temperatures, which is important to remember when designing part geometries and wall thicknesses.

Delrin comes with an impressive range of resistance to chemicals and wear and tear. However, it doesn’t perform well at high temperatures and will start to break down if the heat gets too high.

Depending on the specific application, Delrin can be used as a substitute for metal, unless you require the material properties of steel.

Delrin parts can have a minimum wall thickness of 0.8 mm (0.03 in). This may vary depending on the ratio of wall thickness to the part’s planar dimension. The minimum machining tolerance of Delrin is 0.25 mm (0.01 in). It’s important to note that the higher you go in terms of nominal dimensions, the looser we have to get with tolerances.

Typically, the minimum wall thickness should be at least 1 mm (0.039 in). For more robust strength, we recommend 2 mm (0.079 in), and 2.5 mm (0.098 in) for rigid walls.

The temperature range for working with Delrin parts is -40 degrees Celcius to 120 degrees Celcius.

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

Read article

Want to learn how to design undercuts that don’t cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more. Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, we’ll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.

Read article

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

When producing parts with injection molding, understanding the range of materials that are available is crucial. Find out more about those materials, their properties, and factors to consider when choosing a material for injection molded parts.

Read article

Find out about the manufacturing technique used to injection mold a second material over or around a part to create a new one.

Read article

Want to learn more about die casting? In this article, we’ll take a look at the process, its history and current uses, advantages, design guidelines, and more.

Read article

In this article, we’ll take a look at common factors that influence the cost of injection molding, including equipment, labor, and materials – as well as tips for reducing manufacturing costs.

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

Read article

Want to learn how to design undercuts that don’t cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more. Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, we’ll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.

Read article

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

When producing parts with injection molding, understanding the range of materials that are available is crucial. Find out more about those materials, their properties, and factors to consider when choosing a material for injection molded parts.

Read article

Find out about the manufacturing technique used to injection mold a second material over or around a part to create a new one.

Read article

Want to learn more about die casting? In this article, we’ll take a look at the process, its history and current uses, advantages, design guidelines, and more.

Read article

In this article, we’ll take a look at common factors that influence the cost of injection molding, including equipment, labor, and materials – as well as tips for reducing manufacturing costs.

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read articleShow more

Show less