Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our SLS servicesSource high-performing parts for rapid prototyping and low-volume industrial production with FDM 3D printing. We offer FDM for quick-turn manufacturing using a variety of robust materials for many use cases and can print parts in 1 day.

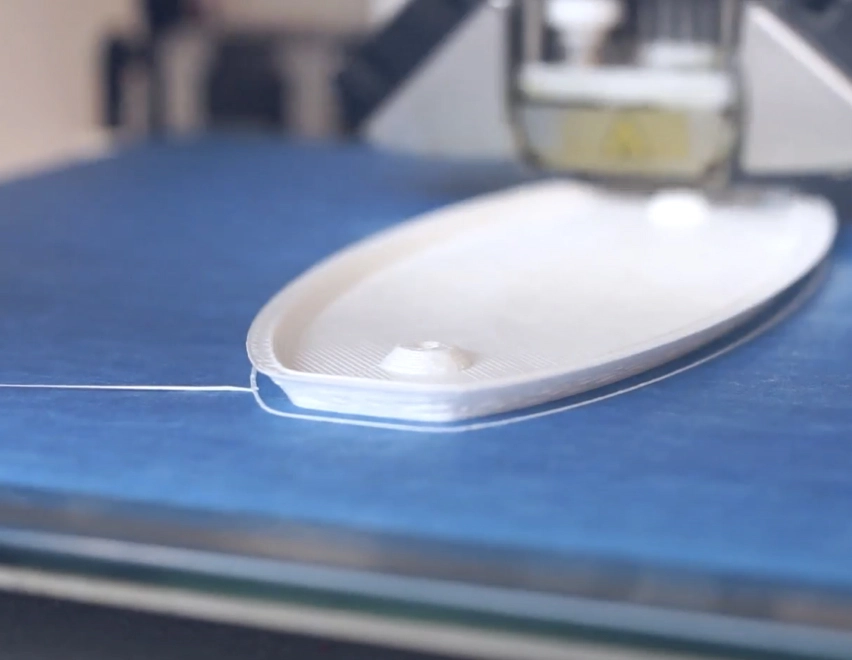

FDM (fused deposition modeling) 3D printing creates custom parts by heating and extruding thermoplastics layer-by-layer. You can use FDM for initial and functional prototyping and low volume production in a variety of strong plastic materials. While FDM is the most affordable 3D printing technology, it’s far more than a small-scale manufacturing solution. 3D printing with FDM means getting access to thermoplastics, including PLA, ABS, TPU, PETG and PEI, and a dimensional accuracy of ±0.5% with a lower limit of ±0.5 mm (0.0196”).

Learn more about FDM 3D printing

FDM 3D printing has two distinct classes: prototyping (desktop) FDM and industrial FDM. These are the key capabilities of both technologies.

| Maximum build size | Standard lead time | Dimensional accuracy | Layer height | Infill | |

|---|---|---|---|---|---|

| Prototyping FDM | 500 x 500 x 500 mm (19.68 in x 19.68 in x 19.68 in) | From 2 business days | ± 0.5% with a lower limit on ± 0.5 mm (0.0196 in) | 100-300 μm | 20-80% |

| Industrial FDM | 406 x 355 x 406 mm* (15.98 x 13.97 x 15.98 in) | 3 business days | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | 100-300 μm | Ultra-light, Light, Solid |

Ideal for fast and affordable rapid prototyping and modeling.

Prototyping PLA

Prototyping PETG

Prototyping ASA

Prototyping ABS

Prototyping TPU

Ideal for higher-volume production and bigger parts with better mechanical properties.

Nylon:

Markforged Onyx

PEI:

ULTEM 9085,

ULTEM 1010

ASA:

Stratasys ASA

ABS:

ABS M30,

ABSplus

| Materials | Price | Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|---|---|

| FDM | 5 | $ | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 100-300μm | 2.0 mm (0.0787’') |

| Industrial FDM | 6 | $$$$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | High level of repeatability, engineering grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98") | 100-330μm | 2.0 mm (0.0787’') |

| Prototyping SLA | 8 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | Smooth surface finish, fine feature details | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") | 50-100μm | 0.2 mm (0.00787’') |

| Industrial SLA | 3 | $$$ | ± 0.2% with a lower limit of ± 0.13 mm (± 0.005") | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 50-100μm | 0.2 mm (0.00787’') |

| SLS | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, supports not required | 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 100μm | 0.5 mm (0.0196”) |

| MJF | 2 | $$ | ± 0.3% with a lower limit on ± 0.3 mm (0.012’') | Design flexibility, supports not required | 380 x 285 x 380 mm (14.9’’ x 11.2’’ x 14.9’') | 80μm | 0.5 mm (0.0196”) |

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to The Protolabs Network Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

Consistent surface finish with no bumps or delamination. Marks left by retraction and layer changing are acceptable.

All support material is removed so that the supported surface has a consistent finish.

All parts are printed with 3 outline / perimeter shells or a wall thickness of 1.2 mm.

FDM is the most cost-effective way to produce custom thermoplastic parts and prototypes.

Lead times are short (typically a few days).

A wide range of materials is available, suitable for prototyping and industrial applications.

FDM is not suitable for parts with very small details due to its low resolution.

Parts are likely to have visible layer lines, so post-processing is required for a smooth finish.

The layer adhesion mechanism makes parts inherently anisotropic.

The table summarizes the recommended and technically feasible values for the most common features encountered in FDM 3D printed parts.

Learn more about how to design parts for FDM 3D printing

| Feature | Recommended size |

|---|---|

| Unsupported walls | 0.8 mm (0.0315 in) |

| Supported walls | 0.8 mm (0.0315 in) |

| Minimum feature size | 2.0 mm (0.0787 in) |

| Minimum hole diameter | 2.0 mm (0.0787 in) |

Learn more about how FDM 3D printing works and how to design the best parts for this additive manufacturing technology.

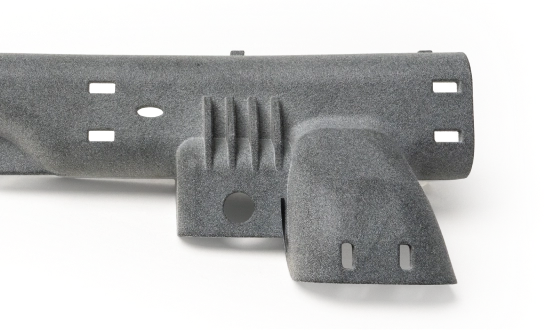

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our SLS services

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our MJF services

Visual prototyping

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our SLA services