What materials have the best repeatability?

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

What SPI surface finishes does Protolabs Network have for injection molding custom parts? Check out the standard SPI mold finishes we offer and our material recommendations to get the most out of injection molding.

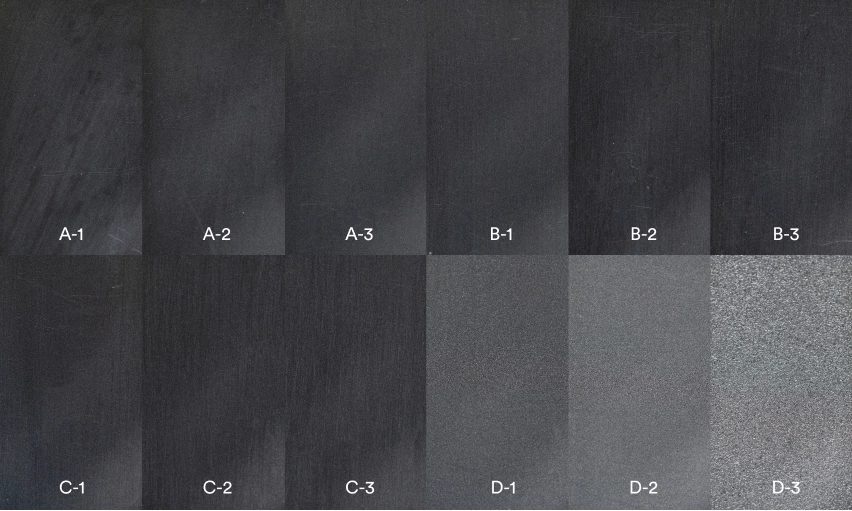

This table contains all of the SPI injection molding surface finishes we offer.

| Finish | SPI* standard | Finishing Method | Typical surface roughness Ra (μm) |

|---|---|---|---|

| Super High Glossy finish | A-1 | Grade #3, 6000 Grit Diamond Buff | 0.012 to 0.025 |

| High Glossy finish | A-2 | Grade #6, 3000 Grit Diamond Buff | 0.025 to 0.05 |

| Normal Glossy finish | A-3 | Grade #15, 1200 Grit Diamond Buff | 0.05 to 0.10 |

| Fine Semi-glossy finish | B-1 | 600 Grit Paper | 0.05 to 0.10 |

| Medium Semi-glossy finish | B-2 | 400 Grit Paper | 0.10 to 0.15 |

| Normal Semi-glossy finish | B-3 | 320 Grit Paper | 0.28 to 0.32 |

| Fine Matte finish | C-1 | 600 Grit Stone | 0.35 to 0.40 |

| Medium Matte finish | C-2 | 400 Grit Stone | 0.45 to 0.55 |

| Normal Matte finish | C-3 | 320 Grit Stone | 0.63 to 0.70 |

| Satin Textured finish | D-1 | Dry Blast Glass Bead #11 | 0.80 to 1.00 |

| Dull Textured finish | D-2 | Dry Blast #240 Oxide | 1.00 to 2.80 |

| Rough Textured finish | D-3 | Dry Blast #24 Oxide | 3.20 to 18.0 |

| As machined | - | Finished to the machinist’s discretion | 3.20 (with visible machining marks) |

To get started with injection molding or get a quick refresher before manufacturing your custom parts, check out our comprehensive guide to injection molding.

SPI surface/mold finishes produce different results depending on the material you use for injection molding components. The tables below detail how to select the right mold finish and materials for your specific application.

| Material | A-1 | A-2 | A-3 |

|---|---|---|---|

| ABS | Average | Average | Good |

| Polypropylene (PP) | Not recommended | Average | Average |

| Polystyrene (PS) | Average | Average | Good |

| HDPE | Not recommended | Average | Average |

| Nylon | Average | Average | Good |

| Polycarbonate (PC) | Average | Good | Excellent |

| Polyurethane (TPU) | Not recommended | Not recommended | Not recommended |

| Acrylic | Excellent | Excellent | Excellent |

| Material | B-1 | B-2 | B-3 |

|---|---|---|---|

| ABS | Good | Good | Excellent |

| Polypropylene (PP) | Good | Good | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Good | Good | Excellent |

| Nylon | Good | Excellent | Excellent |

| Polycarbonate (PC) | Good | Good | Average |

| Polyurethane (TPU) | Not recommended | Average | Average |

| Acrylic | Good | Good | Good |

| Material | C-1 | C-2 | C-3 |

|---|---|---|---|

| ABS | Excellent | Excellent | Excellent |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Excellent |

| Polycarbonate (PC) | Average | Not recommended | Not recommended |

| Polyurethane (TPU) | Good | Good | Good |

| Acrylic | Good | Good | Good |

| Material | D-1 | D-2 | D-3 |

|---|---|---|---|

| ABS | Excellent | Excellent | Good |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Good |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Good |

| Polycarbonate (PC) | Excellent | Not recommended | Not recommended |

| Polyurethane (TPU) | Excellent | Excellent | Good |

| Acrylic | Average | Average | Average |

Need more advice on injection molding custom parts?

SPI surface finishes refer to the predominant global surface finish standard set by the Plastics Industry Trade Association (SPI). It covers the 12 grades of SPI mold finishes. You can also refer to SPI surface finishes as SPI mold finishes.

While SPI surface finishes are widely used around the world, they aren’t the only mold finishes. The other standard to consider is the VDI 3400 texture or surface finish standard. Set by the Society of German Engineers, it covers 45 grades of texture for injection molded parts.

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

Read article

Want to learn how to design undercuts that don’t cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more. Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, we’ll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.

Read article

When producing parts with injection molding, understanding the range of materials that are available is crucial. Find out more about those materials, their properties, and factors to consider when choosing a material for injection molded parts.

Read article

Find out about the manufacturing technique used to injection mold a second material over or around a part to create a new one.

Read article

Want to learn more about die casting? In this article, we’ll take a look at the process, its history and current uses, advantages, design guidelines, and more.

Read article

In this article, we’ll take a look at common factors that influence the cost of injection molding, including equipment, labor, and materials – as well as tips for reducing manufacturing costs.

Read article

What are the most common defects in the injection molding process and how do you avoid them? This article provides six essential design tips for avoid production defects while reducing the cost and lead time of your molded parts.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

Read article

Want to learn how to design undercuts that don’t cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more. Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, we’ll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.

Read article

When producing parts with injection molding, understanding the range of materials that are available is crucial. Find out more about those materials, their properties, and factors to consider when choosing a material for injection molded parts.

Read article

Find out about the manufacturing technique used to injection mold a second material over or around a part to create a new one.

Read article

Want to learn more about die casting? In this article, we’ll take a look at the process, its history and current uses, advantages, design guidelines, and more.

Read article

In this article, we’ll take a look at common factors that influence the cost of injection molding, including equipment, labor, and materials – as well as tips for reducing manufacturing costs.

Read article

What are the most common defects in the injection molding process and how do you avoid them? This article provides six essential design tips for avoid production defects while reducing the cost and lead time of your molded parts.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read articleShow more

Show less