What materials have the best repeatability?

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

Are you new to designing parts for 3D print manufacturing or need a refresher on essential design elements? This article provides the key design elements for creating digital models for 3D printing, no matter the additive manufacturing process.

Every 3D printing technology comes with a distinct set of capabilities and its own design freedoms and restrictions. Whether you are a seasoned engineer who’s well-versed in designing for 3D printing or you are new to the field, it’s always a good idea to go over the most essential factors that make or break a design.

This article covers the key design considerations that apply to 3D printing in general, regardless of the printer you choose for manufacturing your custom parts.

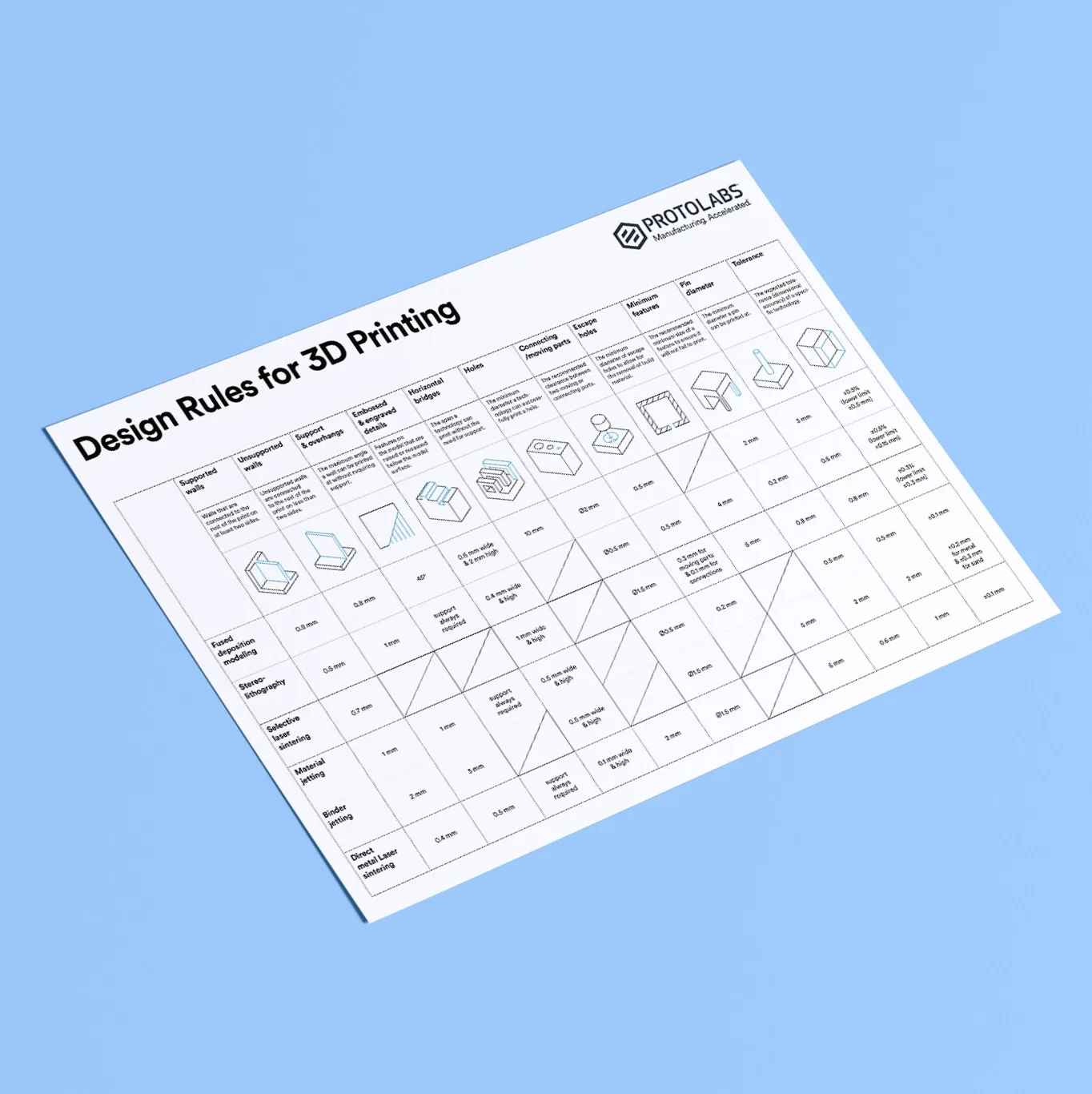

Check out this handy infographic for quick access to every essential design element you may need while creating digital models to 3D print.

Each

3D printing process has its own design advantages as well as some limitations. Let’s break down the key design considerations that apply to every 3D printing technology to keep in mind when designing your next custom parts.

All 3D printing processes build parts layer-by-layer. New layers can’t be deposited onto thin air, so every layer must be printed over some underlining material.

Overhangs are areas of a model that are either partially supported by the layer below or not supported at all. There is a limit on the angle every printer can produce without the need for support material. For example, if you’re printing with an FDM and SLA machine, this angle is approximately 45 degrees.

We recommend limiting your model’s overhangs, as layers printed over support structures usually come out with a rougher surface finish.

The second thing to keep in mind when designing a part to be 3D printed is wall thickness. Every 3D printing process has its own level of precision. FDM, for instance, is the least accurate, while SLA has the tightest tolerances. In terms of part stability, every 3D printing process has a lower limit regarding wall thickness and feature size.

For example, imagine you are an engineer designing a new generation of hang gliders. You’ve chosen to 3D print a scaled-down version of the product to test its efficacy. 3D modeling programs allow you to model the sailcloth of the wing, for instance, but you then encounter problems when you would try to 3D print it. This is because the model’s wall thickness is less than the minimum required for successful printing.

It’s essential to make sure that your 3D designs have walls that meet the minimum required thickness for the printing process you choose. All 3D printers can successfully print components with wall thicknesses greater than 0.8 mm.

Something that is often easily overlooked while designing a 3D model is the fact that the materials used for 3D printing undertake physical change: they are melted, sintered or scanned with a laser and solidified. The heating and cooling of material can cause the parts to warp while printing.

Large, flat surfaces can be especially prone to warping. Warping can typically be avoided by using correct machine calibration and having adequate surface adhesion between your part and the print bed. A good practice is to avoid large flat surfaces and add rounded corners to your 3D models.

When you are creating a 3D model with intricate details, it is important to keep in mind the minimum feature size each 3D printing process can handle. The minimum level of detail is connected to the capabilities and mechanics of each 3D printing process and to the selected layer height.

The process and materials used will have an impact on the speed and cost of your print, so determining whether smaller details are critical to your model is an important design decision.

The most important thing to remember while designing for 3D printing is the fact that your digital design will become a physical object. In the digital design environment, there are no laws of physics to adhere to, such as gravity.

Anything can be "drawn" in 3D on a digital canvas, but not everything can be 3D printed. Knowing the key factors that go into designing 3D models will ensure that you produce digital designs that can be successfully printed.

Want to learn the key design elements for every 3D printing technology?

Design parts for FDM Design parts for SLA Design parts for SLS

Get an instant quote for 3D printed parts by uploading a CAD file.

There is a wide range of CAD programs available for designing 3D models. The most well-known of these (and arguably the best for most applications) is Autodesks AutoCAD, first released for personal computers in 1982. Others include Fusion360, TinkerCAD and Solidworks. For a more in-depth exploration of all the major CAD programs, check out our article on design software.

You don’t need to install any additional software apart from CAD to start producing custom parts with Protolabs Network. Our manufacturing partners are equipped with the best slicing software and a wide variety of machines for all your custom part requirements.

We recommend avoiding overhangs when possible by designing models to be 3D printed. Try not to design your parts with angles over 45 degrees.

All 3D printers used within the Protolabs Network manufacturing network can print parts with wall thicknesses of 0.8 mm and over.

To ensure that your custom parts don’t warp, we recommend avoiding large flat surfaces and using rounded corners in your designs.

It can be quite challenging to choose the right 3D printing technology for your specific applications. FDM is optimal for rapid prototyping and SLS and MJF tend to be better for larger production runs of complex parts, for instance. To help you select the best 3D printing process, we produced this handy guide.

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Multi Jet Fusion (MJF) 3D printing can create highly accurate, complex industrial parts more efficiently - and potentially more cost-effectively - than other industrial 3D printing processes. This article covers how to design parts for MJF, common applications of the technology and key best practices.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

Learn how to avoid low quality 3D prints or unnecessarily large files by exporting your STL file in the correct resolution.

Read article

What are the different materials available for SLA 3D printing? This article compares the main printing resins, including standard, tough, durable, heat resistant, rubber-like, dental and castable, by material properties. Find the best material option for your application.

Read article

A comprehensive guide on designing parts for Binder Jetting, covering the printing process, design specifications and material options.

Read article

How does 3D printing accelerate innovation in the aerospace and aviation industry? In this article, we explain how 3D printing and additive manufacturing are commonly used in aerospace and how they improve prototyping and end-use part production for these industries.

Read article

What are the most common STL file errors and how will they affect your ability to export models for 3D printing? Learn to identify the errors you may encounter when working with STL files and how to fix them so they don't delay your next 3D printing run.

Read article

What is CAD modeling and why is it an essential tool for digital manufacturing? Explore the types of CAD software available for bringing ideas into the physical world via digital 3D modeling. Find the right software tools for your application.

Read article

This article explains how to design Material Jetting 3D printed parts including technical design specifications, materials, limitations and an introduction into the post-processing options available.

Read article

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Multi Jet Fusion (MJF) 3D printing can create highly accurate, complex industrial parts more efficiently - and potentially more cost-effectively - than other industrial 3D printing processes. This article covers how to design parts for MJF, common applications of the technology and key best practices.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

Learn how to avoid low quality 3D prints or unnecessarily large files by exporting your STL file in the correct resolution.

Read article

What are the different materials available for SLA 3D printing? This article compares the main printing resins, including standard, tough, durable, heat resistant, rubber-like, dental and castable, by material properties. Find the best material option for your application.

Read article

A comprehensive guide on designing parts for Binder Jetting, covering the printing process, design specifications and material options.

Read article

How does 3D printing accelerate innovation in the aerospace and aviation industry? In this article, we explain how 3D printing and additive manufacturing are commonly used in aerospace and how they improve prototyping and end-use part production for these industries.

Read article

What are the most common STL file errors and how will they affect your ability to export models for 3D printing? Learn to identify the errors you may encounter when working with STL files and how to fix them so they don't delay your next 3D printing run.

Read article

What is CAD modeling and why is it an essential tool for digital manufacturing? Explore the types of CAD software available for bringing ideas into the physical world via digital 3D modeling. Find the right software tools for your application.

Read article

This article explains how to design Material Jetting 3D printed parts including technical design specifications, materials, limitations and an introduction into the post-processing options available.

Read articleShow more

Show less