What materials have the best repeatability?

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

What’s the ideal material to use when 3D printing parts with FDM? This article compares the most common FDM 3D printing filaments, including PLA, ABS, PET, Nylon, TPU (Flexible) and PC, by their material properties to help you find the best option for your application.

The 3D printing market sees a regular emergence of new materials, which can make choosing the ideal materials for your parts a challenge.

In the case of FDM (fused deposition modeling) 3D printing, PLA and ABS have historically been the two main polymers that manufacturers turn to, though there is now a wide range of materials available. Many of these are playing critical roles in the future of FDM.

We continuously see new products become more popular, including both pure polymers and composites. In this article, we focus on the main pure plastics that exist in the market today, including PLA, ABS, PET, Nylon, TPU (Flexible) and PC. Material suppliers often provide blends or additives for modifying the properties of pure polymers, though these are not covered here.

Choosing the right polymer is essential for getting the right properties for a 3D printed part, especially if your part will be functional. Let’s break down the pure polymers we offer at Protolabs Network.

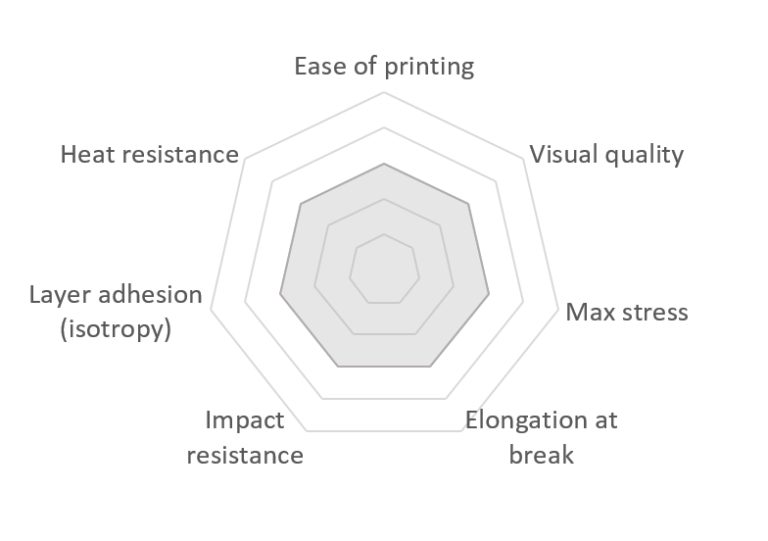

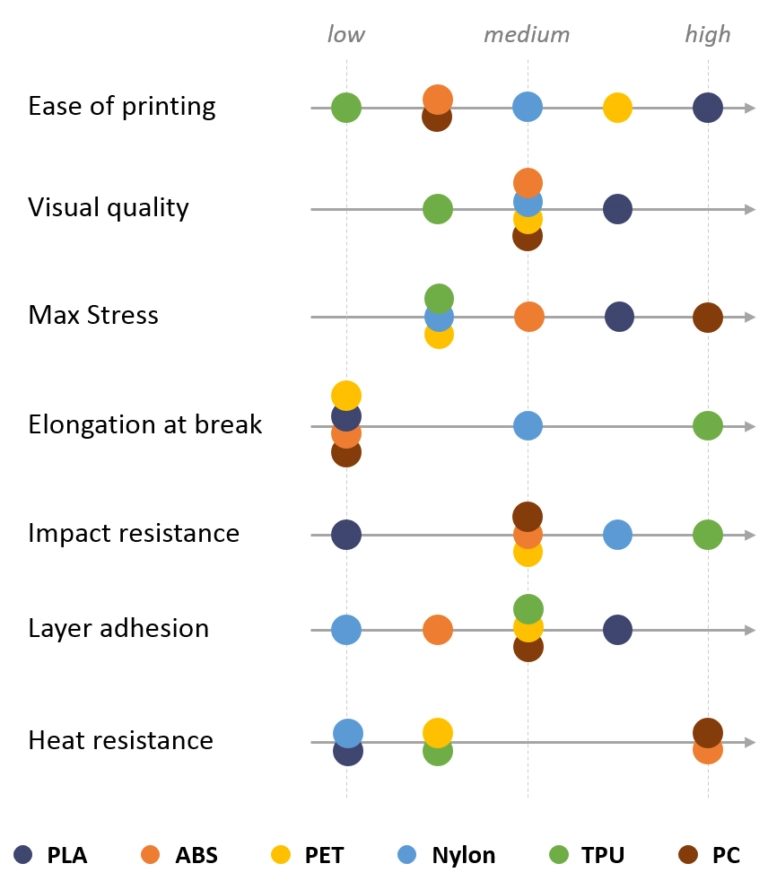

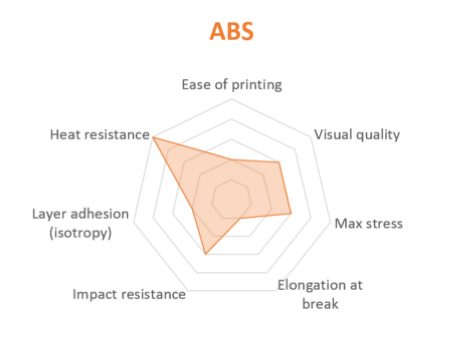

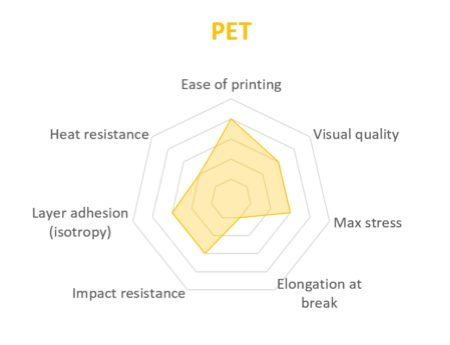

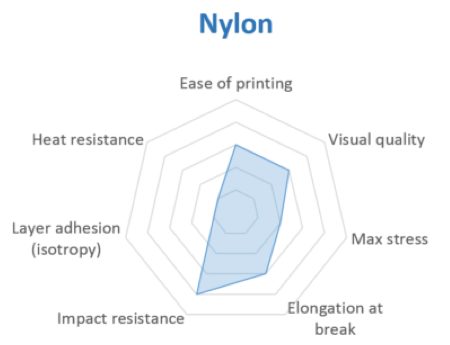

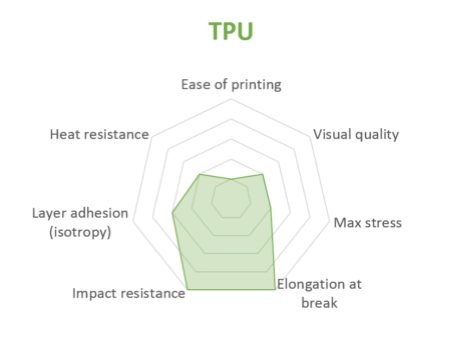

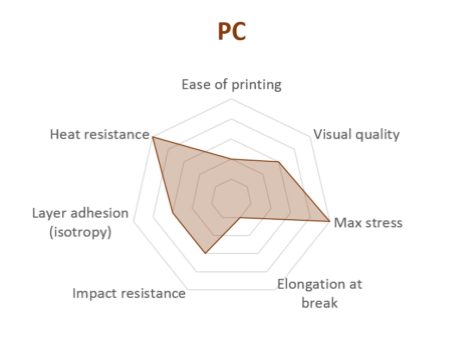

Materials are usually graded along 3 categories: mechanical performance, visual quality, and process. In this case, we further break down these categories to paint a clearer picture of the polymer’s properties. The choice of material really depends on what the user wants to print, so we listed the key decision criteria needed to choose a material (other than cost and speed):

Ease of printing: This is how easy it is to print in a material, with factors including bed adhesion, max printing speed, frequency of failed parts, flow accuracy and ease of feeding into the printer.

Max stress: The maximum stress an object can withstand when slowly pulling on it.

Elongation at break: The ratio between the initial length and the changed length after an object breaks. It’s also called fracture strain.

Impact resistance: The energy required to break an object with a sudden impact.

Layer adhesion (isotropy): This is how well the layers of material adhere to one another. It’s linked to isotropy (uniformity in all directions). The better the layer adhesion, the more isotropic your part will be.

Heat resistance: The max temperature an object can withstand before softening or deforming.

We have ranked each material with the following criteria on a simple scale (low to high). These are relative grades for the FDM process—they would look quite different if other manufacturing technologies were taken into account. Using data from Optimatter, the polymers have been ranked along the different criteria considered.

As a reminder, the grades given in this article are for an average polymer representing the general chemistry, but the performance will vary depending on the actual product or supplier.

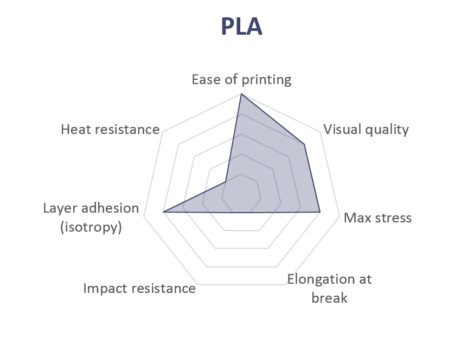

PLA is the easiest polymer to print and provides good visual quality. It is very rigid and actually quite strong, but is very brittle.

PLA is bio-sourced and biodegradable, has good UV resistance and can be post-processed with sanding paper and painted with acrylics. It's also distinctly odorless. On the flip side, PLA does have low humidity resistance and can't be glued easily

ABS is usually picked over PLA when higher temperature resistance and higher toughness are required. It has good abrasion resistance, can be post-processed with acetone vapors for a glossy finish and can be post-processed with sanding paper and painted with acrylics.

ABS is sensitive to UV and potentially comes with high fume emissions. It develops an odor during the printing process.

PET is a slightly softer polymer that is well rounded and possesses interesting additional properties with few major drawbacks.

Aside from its high resistance to humidity and chemicals, PET is also safe to come into contact with foods, is recyclable and has noteworthy abrasion resistance. Like the materials listed previously, it can be post-processed with sanding paper and painted with acrylics.

The only notable drawback is that it's heavier than PLA and ABS.

Nylon possesses great mechanical properties, and in particular, the best impact resistance for a non-flexible filament. It has excellent chemical resistance and is very strong.

For Nylon, layer adhesion can be an issue. The material absorbs moisture and printing with it has the potential to release emissions.

In this analysis, we’re talking only about Nylon 6. We aren't covering Nylon 11 and 12 here.

TPU is mostly used for applications where material flexibility is required, though it also sports very high impact resistance. It's quite abrasion-resistant and isn't affected significantly by coming in contact with oil and grease.

However, TPU is difficult when it comes to post-processing and cant' be glued easily.

PC (polycarbonate) is one of the strongest materials of all for FDM 3D printing and can be an interesting alternative to ABS as the properties are quite similar.

The material can be sterilized and is easy to post-process, though it is UV sensitive.

Ready to start producing custom parts with FDM 3D printiong?

FDM 3D printing can produce parts in a wide range of filament materials. The most common are ABS, PLA and the blends created by material producers. More advanced (and more industrial) FDM printers can use specialized materials that provide benefits like rigidity and higher heat, impact and chemical resistances.

The strongest filament material for FDM at the moment is Ultem 1010. It’s a high-performing PEI thermoplastic that can withstand steam autoclaving and has high thermal stability. If you’re looking for the highest heat and chemical resistances, as well as tensile strength, of any FDM thermoplastic, then ULTEM 1010 is your go-to.

You can’t produce parts with FDM using thermosets, as they degrade when heating, instead of melting.

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Multi Jet Fusion (MJF) 3D printing can create highly accurate, complex industrial parts more efficiently - and potentially more cost-effectively - than other industrial 3D printing processes. This article covers how to design parts for MJF, common applications of the technology and key best practices.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

What’s the best material for machining your parts? Check out this side-by-side comparison of the strength, price and application for CNC plastics and metals (in a handy, printable poster).

Read article

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Read article

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

Read article

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

Read article

Multi Jet Fusion (MJF) 3D printing can create highly accurate, complex industrial parts more efficiently - and potentially more cost-effectively - than other industrial 3D printing processes. This article covers how to design parts for MJF, common applications of the technology and key best practices.

Read article

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

What’s the best material for machining your parts? Check out this side-by-side comparison of the strength, price and application for CNC plastics and metals (in a handy, printable poster).

Read articleShow more

Show less